Environments that might require the use of a respirator could include areas that may be oxygen deficient such as a confined space, or atmospheres that may be contaminated with toxic particulates, vapors or gases (i.e. asbestos, silica, pesticides, certain lab chemicals, paint fumes etc.).

Everyone who wears a respirator at UVM should enrolled in the Respiratory Protection Program (RPP).

The UVM Respiratory Protection Program (RPP) has been developed by the Occupational Health and Safety Office in an effort to assure safe work practices for UVM personnel who have known or potential exposure to airborne pollutants and wear a respirator.

This program also supports UVM personnel who choose to voluntarily wear a respirator in environments where it has been determined that they are not required or recommended.

Please visit the UVM RPP SharePoint Site for specific updates and information.UVM RRP SharePoint Site

How to Enroll in the UVM Respiratory Protection Program

Introduction

Enrolling in the UVM RPP is a multi-step process designed for federal compliance.

These program elements are required for all respirator users at UVM. Personnel who have been approved for voluntary use of disposable filtering facepiece respirators (dust mask, N95) are strongly encouraged to enroll in the program.

The use of respirators is regulated by the Occupational Safety and Health Administration (OSHA) through the Respiratory Protection Standard (29 CFR 1910.134).

1. Manager or Supervisor Completes a Respiratory Hazard Assessment

A Hazard Assessment is a formalization of identifying and documenting any known or potential hazards and making a reasonable estimate of the occupational exposures anticipated to occur as a result of those hazards, including those likely to be encountered in reasonably foreseeable emergency situation. Certain activities may require the use of special work procedures, controls, or PPE, such as a respirator.

An initial Respiratory Hazard Assessment is done once per job task or grouped work procedures. It is then reviewed and updated when the following conditions are met:

- When new equipment or processes are implemented,

- After an accident or injury has occurred,

- The suitability of previously selected PPE needs to be reevaluated, or

- Every three years following the initial assessment.

A hazard assessment will be performed by qualified individual(s), such as managers and/or supervisors.

The Hazard Assessment will include looking at engineering and administrative controls that can be used in the area and determines if you need to wear a respirator at all. If it is determined that a respirator is needed to conduct your work safely, the type of respirator will be determined through the assessment.

Prior to the selection of respiratory protection, the University impacted department/college/unit must make a reasonable estimate of the employee exposures anticipated to occur as a result of those hazards, including those likely to be encountered in reasonably foreseeable emergency situations. As part of the hazard assessment the University has three options to use: Initial Exposure Assessment, Historical Data and/or Objective Data are all acceptable. When using Initial Exposure and Historical Data, a periodic monitoring plan must be in place to ensure exposure levels are acceptable. The affected UVM department is responsible for initiating and maintaining that plan with the support of EHS.

The assessment may indicate that further evaluation is required or if air monitoring sampling may be needed to make a proper determination.

If the results of the Hazard Assessment indicate that you are required to wear a respirator, the next step is to take the required trainings.

Respiratory Hazard Assessment FormA different format of the form can be provided if needed.

If you require assistance, EHS staff are available to assist upon request. To book and schedule an appointment to meet, please go to: Respiratory Hazard Assessment_Bookings

2. Student or Employee Submits a Respirator Use Request

Each UVM Student or Employee required or recommended to use a respirator need to fill out and submit a Request Form.

The Program Administrator will review the Respirator Use Request Form and determine if further investigation of the Hazard Assessment is required or recommended. You and a supervisor may be contacted to set up a time to conduct a Hazard Assessment of your work tasks.

Respirator Use Request Form Upon request, a different format of the form can be provided.

3. Complete Respiratory Protection Training

Who needs to take Respiratory Protection Training?

- Managers and Supervisors that oversee personnel that use respirators.

- Students and Employees that are required or recommended to wear a respirator.

Online and/or in-person training is an annual requirement before you can wear your respirator. You will be trained on the use, care, and maintenance for the type of respirator you have been assigned.

Online training must be completed every year.

Please go to Brightspace Course:

Respiratory Protection Program Training and Enrollment Are you trying to access the training on your phone? Please see instructions here - Phone Access to RPP Training

Training Objectives:

- How the respiratory systems works

- Respiratory hazards and how they affect the respiratory system

- Purpose of respiratory protection

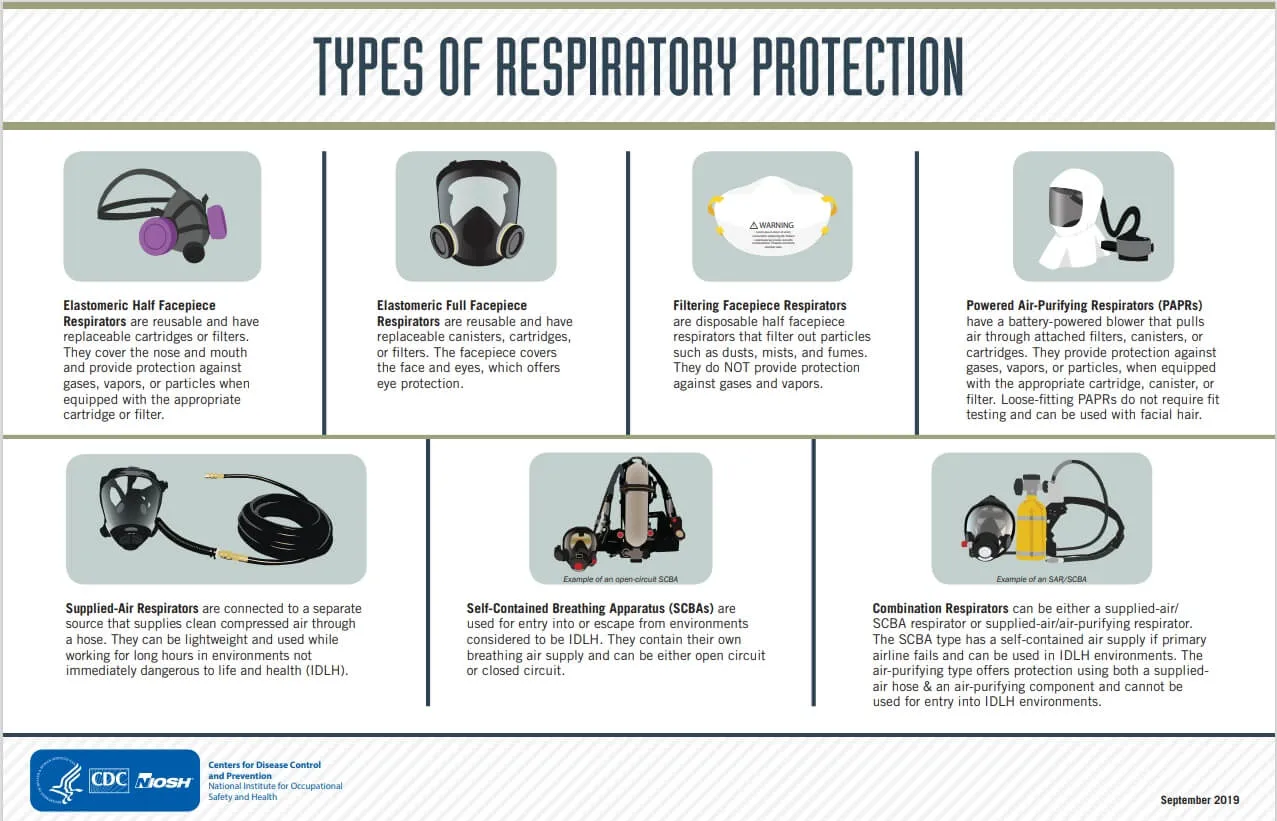

- Different types of respirators and their purposes

- Proper fit, inspection, cleaning, and disinfecting, and storage of respirators

- How to completely disassemble and assemble a respirator

- Medical evaluations

- Hierarchy of controls

Hands-on or Site-Specific training may be deemed necessary.

4. Obtain Medical Clearance

It is required to have an initial medical evaluation prior to using a respirator and then resubmitted every three (3) years. Certain employees may require more frequent medical evaluations, such as employees in the Asbestos Management Program, the Lead/Lead Based Paint Program, or employees who are covered by the OSHA Hazardous Waste Operations and Emergency Response (HAZWOPER) standard.

If you are a student and have a MyWellbeing Account

Please go to

MyWellbeing Account Login Login (using your NetID) to the Student Health Portal and from the home page, click on “Survey & On-Demand Questionnaires”. Under On-Demand Questionnaires, select the "OSHA Respirator Medical Evaluation".

If you are a UVM Employee (Staff and Faculty Members Only)

Please go to

Champlain Medical Urgent Care | South Burlington, VT

A health care provider will review your medical questionnaire and determine if you are medically cleared to wear a respirator. UVM's Occupational Health Program staff will contact you by email with the medical evaluation results.

5. Get a Fit Test

Once you have obtained medical clearance, you must be fit tested to ensure the proper fit and size of your respirator.

There are two categories of fit tests

Qualitative (QLFT) – Relies on the individual's response to a test agent (e.g., irritant smoke). QLFT is used for fit testing negative pressure APRs that must achieve fit factors of less than 100.

Quantitative (QNFT) - Involves a numerical measurement of mask leakage

Concentration of a substance in ambient air/Concentration inside the respirator when worn

E.g., Condensation nuclei counter (TSI Portacount). Used for fit factors of 100 or greater. Must yield a fit factor of 100 or greater for half-mask or 500 or greater for full facepiece

For a Fit Test employees will be instructed to: 1) breathe normally, 2) breathe deeply, 3) turn head side to side, 4) move head up and down slowly, 5) read the VOSHA rainbow passage, 6) grimace, 7) bending over, repeatedly (or alternative to simulate physical demands of work on the device), 8) breathe normally.

An appointment for a fit test can be booked and scheduled by going to:

EHS staff may contact you to schedule your fit test after you have been medically cleared.

Fit testing is an annual requirement. Additional fit tests should be scheduled during the year if you have had significant visible changes to your facial structure that could impact fit (dental surgery, significant weight loss/gain) or you are unable to get a good seal during a user seal check.

During the fit test, you will be shown the following:

- How to put on your respirator correctly,

- How to achieve a comfortable fit, and

- How to conduct a user seal check.

How To Prepare for Your Fit Test:

- Bring your personal respirator if you have already been assigned a make and model. Otherwise, several make and model sample respirators are available for those who do not yet have one.

- Bring proof of your medical clearance.

- Coming to your appointment, you CAN NOT have facial hair, jewelry, or cosmetics (excessive sunscreen, moisturizer, makeup, etc.) that impede on a proper fit. If this is not possible, contact ohealth@uvm.edu.

- Please avoid eating thirty minutes before your scheduled appointment.

- If you are a smoker, please refrain from smoking at least 1 hour before your fit test.

A fit test can take approximately 20-30 minutes. If for some reason you cannot keep your scheduled fit test appointment time, contact ohealth@uvm.edu in advance. A technician is scheduled to conduct your fit test - please be respectful of their time.

6. Stay Up to Date on Program Requirements

The Medical Evaluation Questionnaire must be submitted every three years. Certain employees may require more frequent medical evaluations.

Fit testing and training are annual requirements and must be completed every year.

These program elements are required for all respirator users at UVM.

Determining Voluntary Respirator Use

Important Information for Respirator Use

Frequently Asked Questions

Additional Resources and Information

- OSHA Regulations on Respiratory Protection 29 CFR 1910.134

- OSHA Respiratory Protection General Guidance

- OSHA Quick Card - Respirators

- OSHA Safety and Health Topics: Respiratory Protection

- NIOSH Work Safety and Health Topics - Respirators

- NIOSH Pocket Gudie to Chemical Hazards

- UVM Chemical Use Planning Form (PDF)