Proper management of fresh produce during transport is important to maintain product quality and reduce risk of contamination. Consistent delivery of fresh produce in top condition helps meet buyer expectations and builds customer loyalty.

Design Goals

Body

- Start cool: perishable product is harvested when it is cool, or produce is pre-cooled before transport.

- Maintain proper temperature and humidity: crops remain cool and do not lose moisture during transport.

- Keep it clean: clean, covered delivery space minimizes risk of cross-contamination during transport.

Design Elements

Body

- Crops are harvested early in the day to minimize “field heat” that must be removed later to prevent wilting and reduce spoilage.

- If crops require pre-cooling before shipment, this is done promptly and adequate time is available before transport (it may take 6-12 hours to remove field heat, depending on conditions).

- If crop containers are placed in cold storage to remove field heat, adequate space is maintained around containers to allow air movement and uniform cooling.

- Use of fans / forced air through moist crops in cooler can accelerate removal of field heat though evaporative cooling.

- If perishable product is transported without refrigeration: product starts out cool, transport time is kept short (2 hours or less in warm weather), and if possible, a large mass of product is transported during a cool time of day (early morning).

- Transport vehicle refrigeration system is properly maintained and temperatures are monitored; delivery vehicle has adequate insulation.

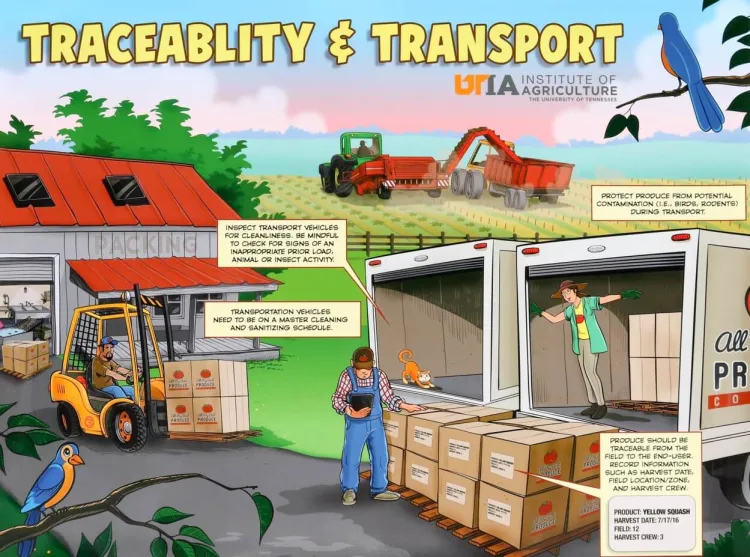

- Transport vehicle is thoroughly cleaned between uses to minimize risk of cross-contamination; shipping container surfaces are clean when loaded into vehicles.

- If transport vehicle is ever used to move potential contaminants (e.g. garbage, recycling, agricultural chemicals, compost) it is thoroughly cleaned and sanitized before it is used for transporting produce.

Benefits

Body

- Clean, cool transportation conditions help maintain fresh produce quality, supporting customer satisfaction and long-term market viability.

- Keeping transport vehicles clean and at appropriate temperature during produce delivery is a regulatory requirement and reduces risk of cross-contamination.

Photos

Body

Authors: Hans Estrin and Vern Grubinger, UVM Extension

This work is supported by the Food Safety Outreach Program Name, project award no. 2023-70020-40688, from the U.S. Department of Agriculture’s National Institute of Food and Agriculture. Any opinions, findings, conclusions, or recommendations expressed in this publication are those of the author(s) and should not be construed to represent any official USDA or U.S. Government determination or policy.