Dunk tanks are commonly used for rinsing fresh produce to remove soil and field heat. These tanks should be durable, stable, easy to clean, and set up for employee comfort.

Design goals

Body

- Fast to fill and empty: Water input and outlet are properly sized and easy to control. Large hose or pipe diameter allows high volume flow. Water pressure is sufficient. Quick-turn handles or valves for starting/stopping water fill. Large drain hole(s) for release of water.

- Sufficient volume of water for effective rinsing: Deep, large-volume containers hold at least 20 gallons of water to a depth of at least 12 inches.

- Maximize employee comfort, efficiency, safety: Tank water level when full is at average waist height, to avoid bending and reaching. Tanks are stable and cannot tip over. There is plenty of room to move around tanks when handling produce.

- Easy to clean: Tanks are made of durable, non-rusting, non-porous material with a smooth surface such as high-grade plastic, enamel, or stainless steel. There are no cracks, crevices, or rough surfaces.

- Efficient flow of produce: Adjacent staging areas (counters, tables) hold produce before and after rinsing; tools (baskets, nets) assist with moving produce into and out of tanks.

Design Elements

Body

- Area under tank(s) is stable and does not retain water. A cement pad, crushed stone, or solid wooden decking can support the weight of the tanks when filled with water. Cement is durable, cleanable if smooth, and allows for use of wheeled equipment. Crushed stone or wood decking may cost less. Do not place tanks over soil or sod surfaces, or on any material that retains water.

- Water drains into an area that can handle the volume and force of the discharge. This can be accomplished with a lay-flat hose emptying into a turf-covered swale, a crushed stone dry-well, or a settling pond that drains onto a turf-covered field.

- Rapid water drainage is essential for efficient wash-pack production. Larger tanks have a 2-inch bung hole with easy-to-remove stopper. Bulk-dump of water by tipping may be possible for small tanks under 30 gallons.

- Tank support is strong and stable. Examples include cinder blocks, 4 by 4-foot wooden rails, or steel frame.

- Tools for gentle agitation of water in tanks can help dislodge soil and debris from produce surfaces. Plastic paddles, if used carefully, can avoid damaging fragile leaves. Waterproof gloves should be provided if employees agitate produce by hand. Consider installing bubblers for automated agitation in larger tanks.

- Space around tanks is adequate to accommodate pre- and post-rinse activities such as produce drop-off, drying, packing, bin stacking, etc. Consider a 3 by 3 foot (pallet size) harvest container drop zone before the first tank, and a 4-foot wide work area in front of tanks for people loading, rinsing, and removing produce from tanks.

- Tanks are placed near good lighting. Windows or light fixtures allow employees to clearly see produce while rinsing. It is easy to miss damaged produce in poor light. If natural light is sub-optimal, consider high-quality full-spectrum LED lights.

- Cleaning tools are visible and located near tank, with cleaning SOP posted nearby. Set employees up for success in following cleaning protocol.

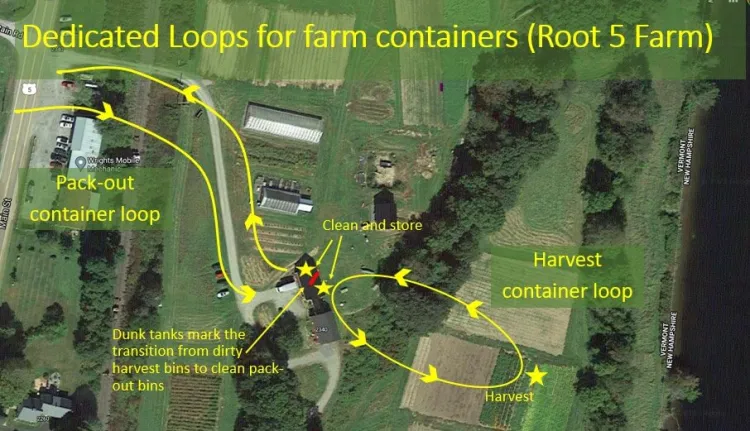

- Clean and dirty containers remain separated, on either side of tanks. Dunk tanks mark the interface between harvest and pack out. Food safety risks are reduced, and labor efficiency can be increased when harvest bins always stop at the dirty side of the dunk tanks, and every contact surface after produce is rinsed clean.

Benefits

Body

- Effective rinsing practices reduce the risk of cross-contamination, when pathogens move through water from one piece of produce to another.

- Properly sized tanks, hoses, and drains allow for speedy filling and draining, saving time.

- Tanks positioned to optimize employee comfort can improve efficiency, reduce labor costs, and avoid injuries.

- Tanks made of smooth, non-porous material in good condition can be properly cleaned so all debris is easily removed, and so they won’t harbor pathogens.

Photos

Body

Authors: Hans Estrin and Vern Grubinger, UVM Extension

This work is supported by the Food Safety Outreach Program Name, project award no. 2023-70020-40688, from the U.S. Department of Agriculture’s National Institute of Food and Agriculture. Any opinions, findings, conclusions, or recommendations expressed in this publication are those of the author(s) and should not be construed to represent any official USDA or U.S. Government determination or policy.