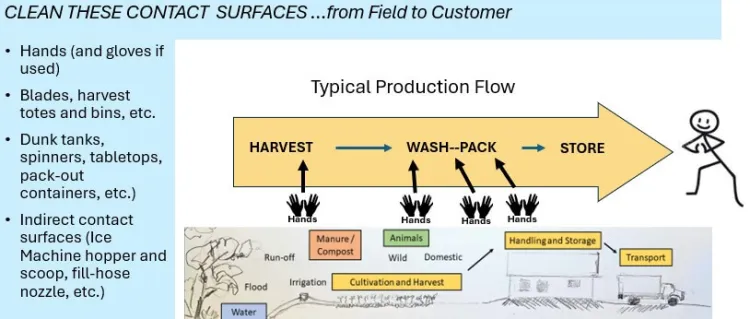

Good cleaning plans describe key procedures for reducing risk in a way that is clear and helpful to employees, supporting consistent implementation of cleaning routines. A good plan lowers risk while increasing operational efficiency. Plans should differentiate between surfaces that contact food and those that don't, specifying what to clean, how, and when.

Design Goals

- Cleaning plans are known. Employees are aware, and trained in, all cleaning protocols for different items and locations on the farm, including hands, harvest containers and tools, washing, sorting and packing equipment and surfaces, storage spaces, transport vehicles, etc.

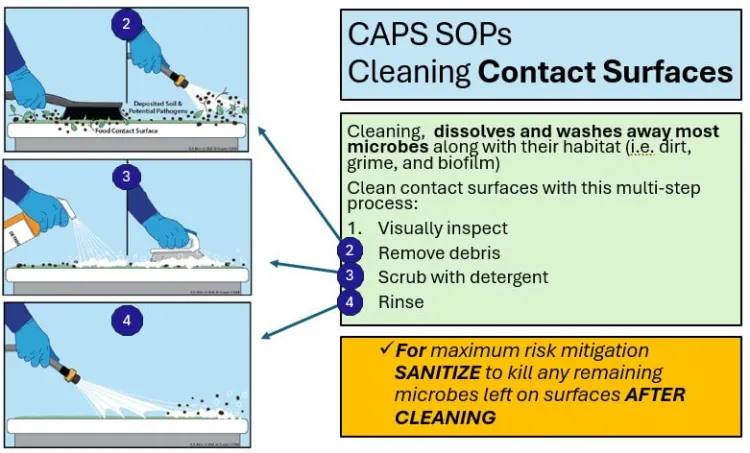

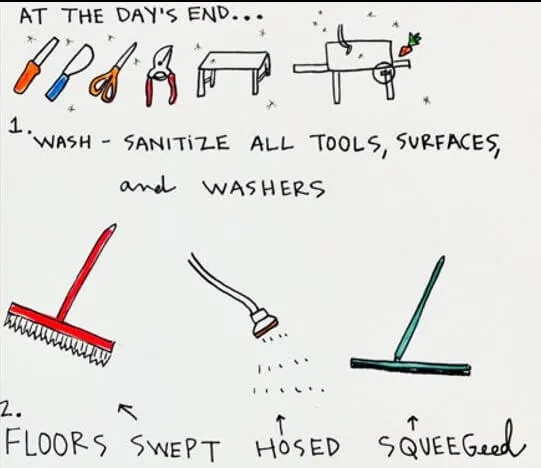

- Different cleaning procedures are understood. Employees understand technical and functional differences between “thorough” (4-step) and “quick” cleaning SOPs (Standard Operating Procedures), and the difference between cleaning and sanitizing (after cleaning).

- Clean is differentiated from dirty. Clean containers are easily distinguished from dirty (e.g. dirty bins face up, clean bins face down to drain and dry; field containers are a different color than storage containers).

- Higher risk produce has a higher cleaning standard. Contact surfaces, containers and handling areas for produce typically consumed raw are cleaned most thoroughly.

- Risk of cross-contamination is minimized. Employees are empowered to continually assess risks to avoid accidental contamination. Adjacent non-contact surfaces (e.g. bin exterior, sink backsplash, floor) are cleaned frequently enough and strategically (albeit less frequently than contact surfaces) to minimize cross-contamination of contact surfaces.

Design Elements

- A "master cleaning plan" lists all cleaning SOPs on the farm, from field to market, and outlines how and when items are cleaned. A notebook of all individual cleaning SOPs is readily available for employees to refer to.

- Individual cleaning SOPs, or key steps in an SOP, are near where they are to be implemented, e.g. storage area has cleaning steps on the wall by the door. The use of images may be helpful in addition to text.

- Employees are trained in all concepts and terminology found in cleaning SOPs such as: inspection, quick-cleaning, dry-cleaning without water, cleaning with detergent, sanitization, rinsing, drying, and cross-contamination prevention.

- Employees are trained to inspect and assess risks as part of cleaning to avoid accidental contamination caused by degraded or contaminated tools or equipment, chemical spills, contact with the floor or ground, potential wildlife exposure, etc.

- Critical cleaning procedures are consistently documented when completed, using a checklist with dates, signed logbooks, etc. to ensure follow though on cleaning SOPs and to provide accountability.

Benefits

- Having effective cleaning plans for all aspects of fresh produce handling on a farm can reduce food safety risks.

- Implementing regular cleaning routines based on written plans can increase labor efficiency and employee morale because people know what they are supposed to clean, when, and why.

- Good cleaning plans support improved organization of materials and activities on a farm, because it is clear what is needed, and where, to complete cleaning tasks.

Photos

Related Resources

- Contact Surface Cleaning SOP (Standard Operating Procedure) (CAPS Resources)

- Farm Container-Simple Cleaning SOP Template (CAPS Resources)

- Bulk Bin Cleaning SOP--Template (CAPS Resources)

- Orchard Picker Bucket Care SOP--Template (CAPS Resources)

- • A Guide to Cleaning, Sanitizing, and Disinfecting for Produce Farms (UVM Extension Agricultural Engineering)

Authors: Hans Estrin and Vern Grubinger, UVM Extension

This work is supported by the Food Safety Outreach Program Name, project award no. 2023-70020-40688, from the U.S. Department of Agriculture’s National Institute of Food and Agriculture. Any opinions, findings, conclusions, or recommendations expressed in this publication are those of the author(s) and should not be construed to represent any official USDA or U.S. Government determination or policy.

Photos

Photos coming soon