Cleaning removes germs and dirt from surfaces using soap or detergent and scrubbing; subsequent sanitizing lowers the number of germs on surfaces. Having the right cleaning and sanitizing tools and products on hand, accessible, and well-organized supports implementation of produce safety Standard Operating Procedures (SOPs) on farms.

Design Goals

- Cleaning tools and products are identified. The tools and products needed to clean and sanitize surfaces that come in contact with fresh produce are identified in the farm's cleaning SOPs.

- Cleaning tools and products are accessible. Appropriate cleaning and sanitizing tools and products are stored near where they are used, visible, and easy to reach.

- The right stuff is used safely. Cleaning and sanitizing tools and products are appropriate for their intended use, and used safely.

Design Elements

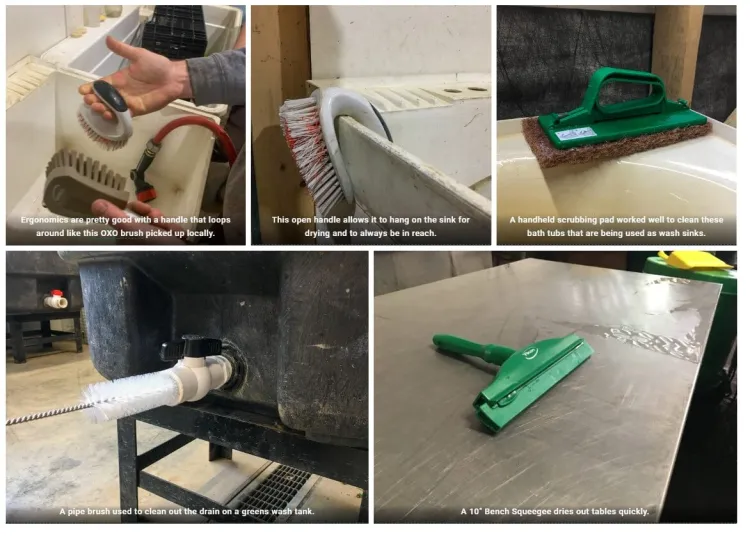

- Tools (brooms, brushes, scrubbers, sponges, squeegees, etc.) are hung or stored where they can be seen by employees and can dry out between uses.

- Protective equipment (gloves, goggles) is stored where easily accessible.

- Tools are durable and designed to reach their target surfaces (e.g. curved brush head to scrub inside edges of harvest containers).

- Detergent and/or soaps are:

- non-toxic and free from unnecessary dyes and fragrance (e.g. have “free and clear” or “family safe” labels).

- easy to open; dispensers release small amounts, to create visible but minimal suds, optimizing the amount of rinse water needed.

- used at the appropriate dilution for the application, as listed on the label (e.g. a concentrated cleaner diluted 10:1 to spray for surface cleaning).

- completely rinsed off and produce is scrubbed as needed.

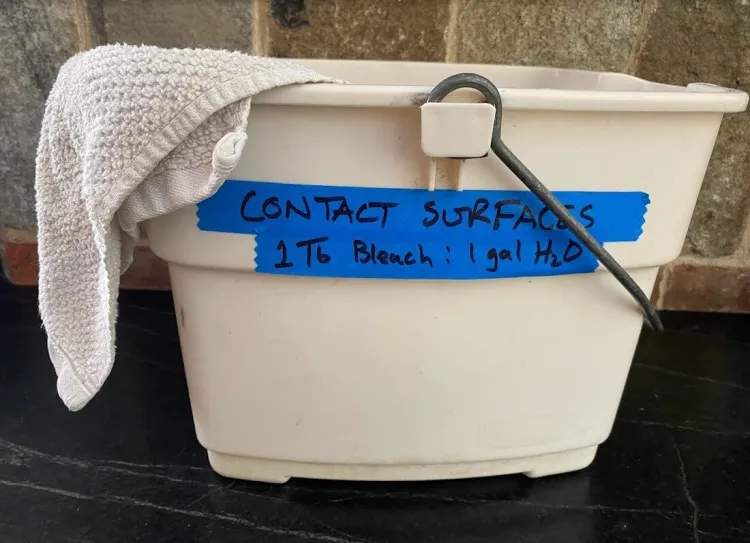

- Sanitizers are EPA-approved for use on food contact surfaces, and label instructions are followed. Common active ingredients are quaternary ammonium compounds (quats), chlorine (hypochlorites), iodophors, peroxyacetic acid (PAA), and hydrogen peroxide.

- Caustic or toxic material containers are clearly labeled and have spill-free dispensers. It is a legal requirement to follow the label of sanitizer products, and for employees to use protective equipment when handling concentrated solutions.

- Employees are trained to use protective gear to prevent accidental exposure to concentrated sanitizers (e.g. nitrile gloves, safety glasses or goggles, spill-free dispensers).

Benefits

- Easy access to appropriate cleaning and sanitizing tools and supplies supports regular and effective management of food safety risks on produce contact surfaces.

- Effective cleaning and sanitizing reduces risk of cross-contamination and can prevent premature spoilage of fresh produce.

- Well-organized tools and supplies can support efficient use of labor.

- By using products for their intended use, following their labels (a legal requirement for surface sanitizers), and using protective equipment when handling concentrated solutions, cleaners and sanitizers support safe and powerful risk reduction.

Photos

Authors: Hans Estrin and Vern Grubinger, UVM Extension

This work is supported by the Food Safety Outreach Program Name, project award no. 2023-70020-40688, from the U.S. Department of Agriculture’s National Institute of Food and Agriculture. Any opinions, findings, conclusions, or recommendations expressed in this publication are those of the author(s) and should not be construed to represent any official USDA or U.S. Government determination or policy.