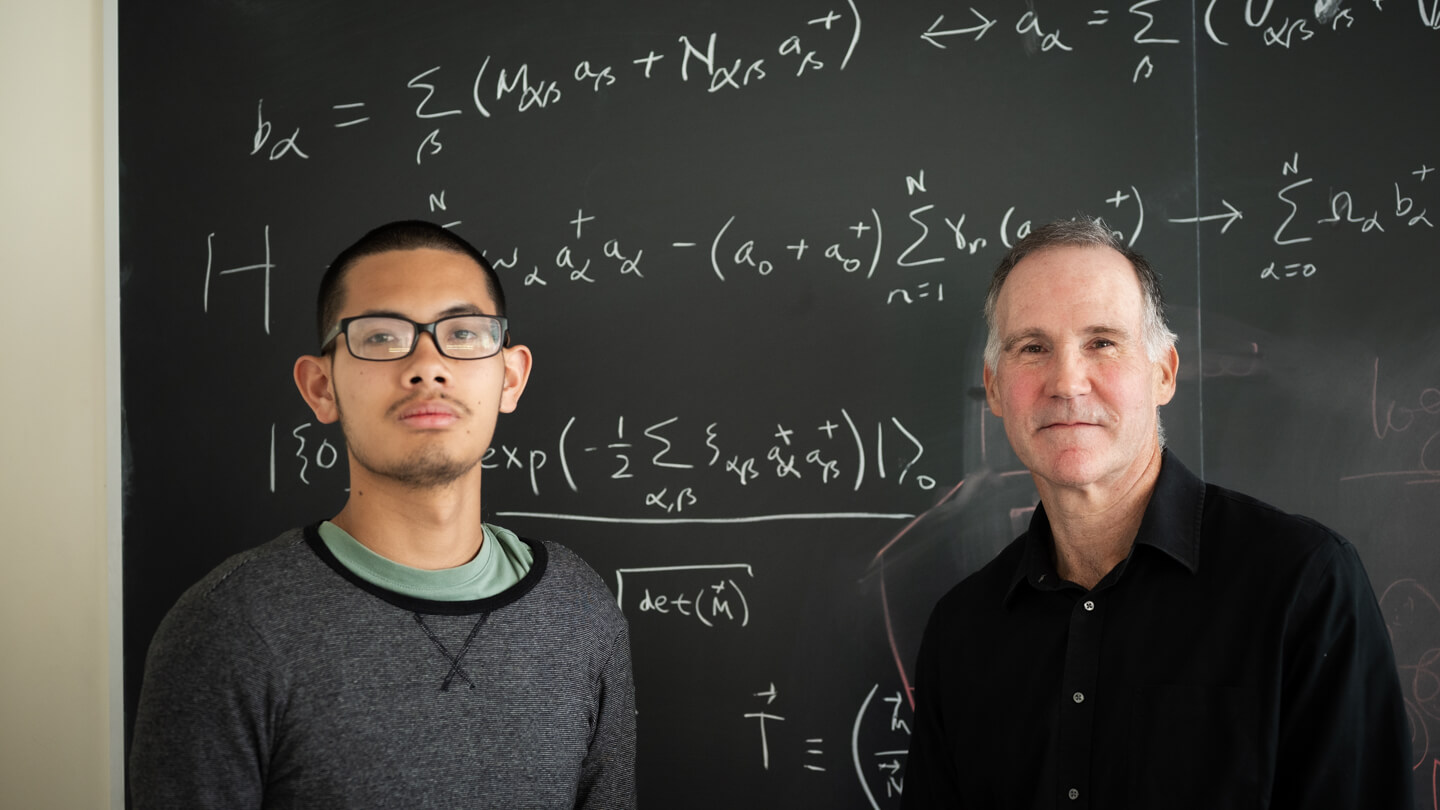

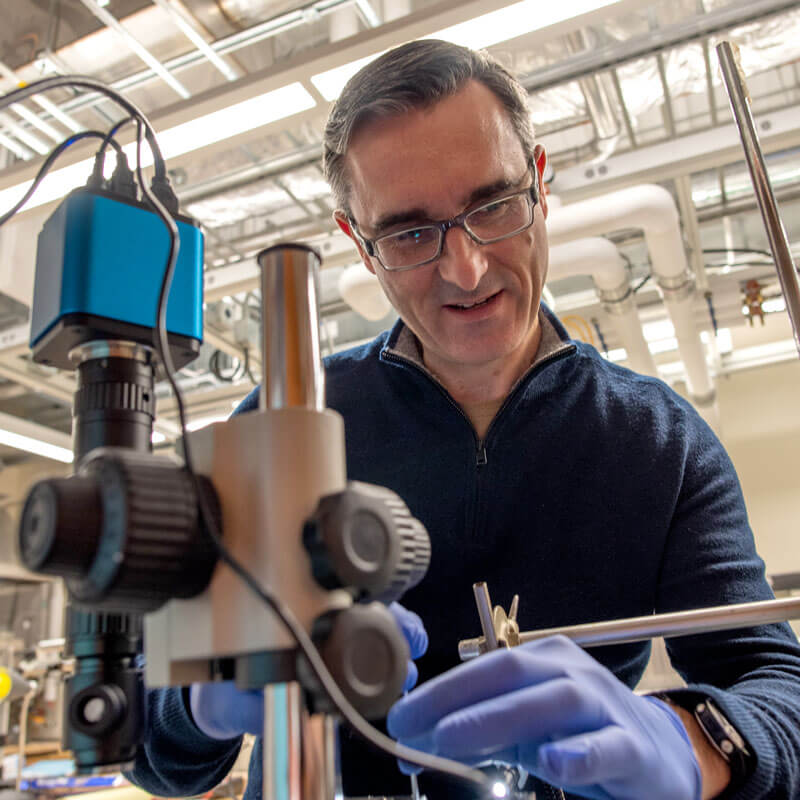

At the College of Engineering and Mathematical Sciences, we are more than educators. We are a community of problem solvers, inspiring each other to build true world solutions that will lead to healthy, sustainable societies.

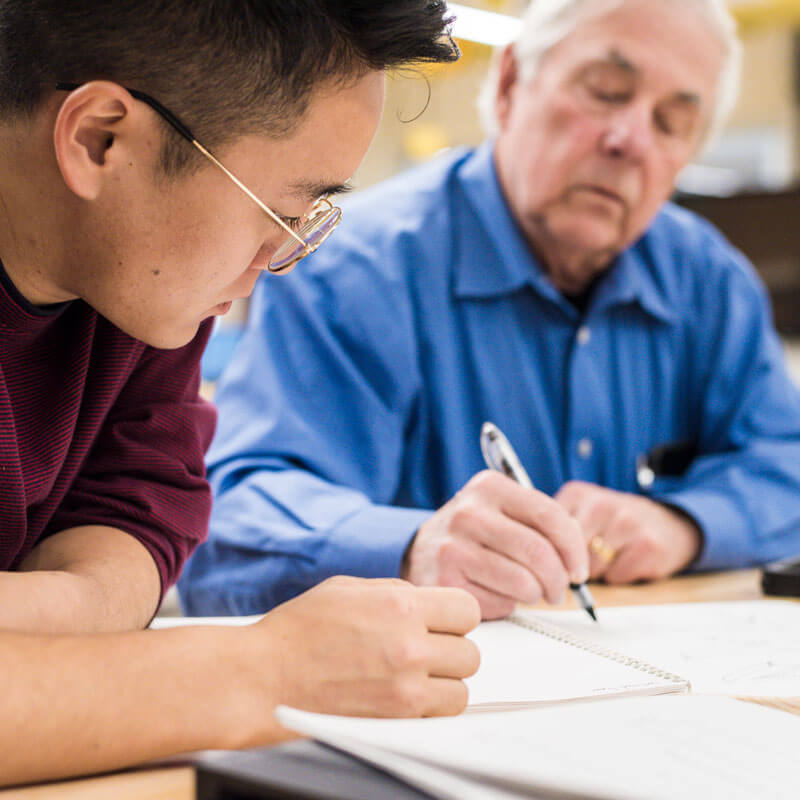

Our approach is personal, fostering a culture of collaboration that’s as driven by student-to-student connections as by our world-class faculty and advanced research opportunities. You may enter UVM a little unsure, eager, and excited for the next chapter. By the time you’re ready to leave, you’ll be poised to change the world.

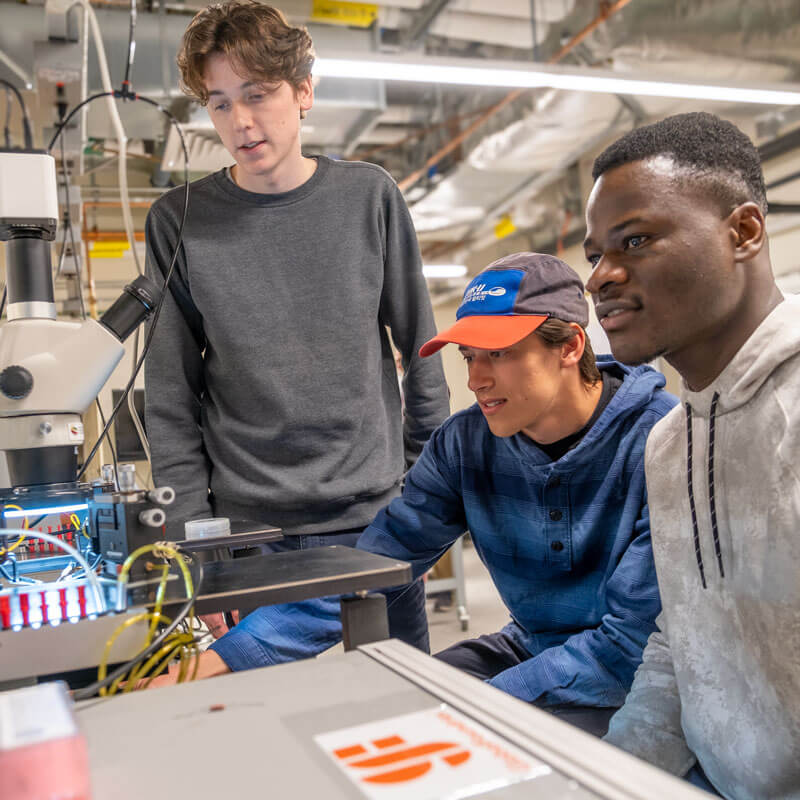

academics A hands-on, team-based approach

By the numbers

- 15 accelerated master's programs in STEM-related fields

- 8 petaflops supercomputer

- Top 10 "Most Innovative Tech Hub" - Forbes

Quick Links by Audience