The Vermont growing season offers a short window to produce, harvest, and store nutrients in the form of forages for dairy cattle, including hay crop silage and corn silage. This process can be challenging, but the result is rewarding for you, your livestock, and your operation. The goal is to harvest crops at the correct stage of maturity and store them so that oxygen is rapidly excluded and they begin to ferment. During the fermentation process, there is a quick drop in pH levels, which preserves the nutrients and dry matter of the feed by creating an undesirable environment for the growth of harmful yeast and molds. Good management during the bunk filling and packing process is key to fermentation and preservation success.

Bunk Density

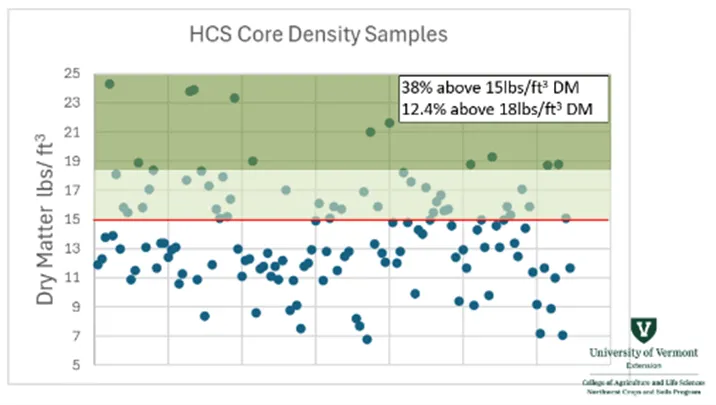

Bunk density is expressed in pounds of dry matter per cubic foot (lbs DM/ft3). To measure bunk density, we use the Dairy One Forage Probe to drill into the bunk face and collect a core sample. The core is then measured, and the sample is processed to determine dry matter. Using the Dairy One Density Calculator, we collect values that determine the density of the feed stored at the sample location. Density is not necessarily consistent across the bunk face or pile; therefore, we often take multiple core samples when evaluating bunk density.

The minimum goal for the density of feed stored in bunks or piles is 15lbs DM/ft3. Optimal density is 18lbs DM/ft3 or greater. This level of bunk density indicates that oxygen has been effectively excluded, promoting good fermentation and preservation of nutrients. Feed stored at less than 15lbs DM/ft3 likely has greater exposure to oxygen, which promotes nutrient degradation and the growth of potentially harmful yeasts and molds.

The UVM Extension NWCS Team has been measuring bunk density on farms across Franklin County over the past two years. Figure 1 shows the range of densities observed from 96 core samples of hay crop silage stored in cement bunks, piles on cement pads, and in ag bags. Samples were taken from multiple locations on the open bunk face. Approximately 60% of the samples fell below the minimum density of 15lbs DM/ft3, indicating less than ideal potential oxygen exposure, which resulted in deterioration of feed quality.

Educating the Community

To address this problem and help farmers improve overall feed quality,

Amber Machia, UVM Extension NWCS Research Specialist, and Kurt Cotanch, an independent dairy nutrition consultant, threw a Preservation Party at the 2025 UVM Extension Annual Crops & Soils Field Day. (Figure 2) They presented their research findings to a group of farmers and technical assistance providers. This included a sensory experience where guests smelled and touched various forage samples and guessed which one was the highest quality feed. They also taught their audience about management factors that affect density, so they can increase the overall quality of feed.

Management factors that affect density include:

- Packing weight – recommended minimum of 800lbs packing weight per ton of forage delivered per hour

- Delivery rate – fill rate should be based on total available packing weight (the pushing tractor is only packing ~60% of the time)

- Dry matter & chop length of harvested feed – dry forage that is cut long is harder to pack tightly

- Layer thickness – should not exceed 6”

- Slope of ramp – if too steep, tractor tires may spin and disrupt packed forage below

- Feed storage infrastructure – adequate space is needed to safely access the pile or bunk. Layered feeds make it difficult to consistently attain optimal packing density.

Interested in assistance with weighing your bunk packing equipment and determining the optimal fill rate and management for your scenario? Interested in having core samples taken of your existing stored feed to determine the density that you are achieving? Contact Amber Machia (802)656-7615 or amber.machia@uvm.edu.