This fall, the Northwest Crops and Soils (NWCS) team is reaping what we “sew”- in more ways than one. With the help of our local collaborators, Battenkill Fibers and Muriel’s of Vermont, we produced the first all-local hemp fiber clothing in the modern history of the Northeast. Using hemp grown at Borderview Research Farm in Alburgh, Vermont, Corriedale wool from the Finger Lakes region, fiber processing knowledge and expertise from Battenkill Fibers in Greenwich, New York, and the fashion design and knitting capabilities of Muriel’s of Vermont in North Hero, we produced three wool-hemp sweater vests. More than a year in the making, this achievement stands as proof of what’s possible for sustainable, locally produced fibers. This is the story of how it came to fruition.

An Emerging Crop

Industrial Hemp (Cannabis sativa L.) is an emerging food and fiber crop in the Northeast. It is a non-psychoactive variation of Cannabis sativa defined by its low delta-9-tetrahydrocannabinol (THC) content threshold of 0.3%. The NWCS team began trialing hemp for research in 2016. Since then, they have honed their skills at growing the crop for various applications, such as food, flower, biomass, and fiber. Watch this video to see Laura Sullivan introduce the fiber hemp trials to guests at the 2025 Annual Field Day at Borderview Research Farm.

Watch Laura Sullivan present our fiber hemp program. (YouTube video)

Why Fiber?

The fashion industry on a global scale is one of the highest-polluting industries in the world. Fibers used in clothing are either natural or synthetic. Natural fibers are derived from plants and animals. They include cotton, wool, silk, hemp, and more. Alternatively, synthetic fibers are man-made and often derived from petroleum by-products. These include polyester, nylon, and acrylic. Most large corporations forego lasting, durable fabrics made from natural fibers for cheaper, synthetic alternatives to maximize profit. Clothing made with synthetic materials doesn’t last and prompts people to buy new clothes more often, which then overwhelmingly end up in landfills worldwide, amounting to 92 million tons of garments in landfills every year (Chen et al., 2021). Hemp fiber could be a solution to this problem, given its high durability and proclivity to circular design. Circular design is a term used to describe designing products that exist in a closed loop of carbon sequestration. All textiles- whether natural or synthetic- are carbon-based, but only those derived from the soil can return to the soil at the end of their lifespan. Natural fibers like hemp are inherently compostable and biodegradable. Composting natural materials helps to build healthy soils. Synthetic fabrics, on the other hand, are made of carbon derived from oil, which has been extracted from the lithosphere. They can never be returned to their original carbon sink, therefore perpetuating a cycle of extraction which leads to trapped emissions and an exacerbated greenhouse effect.

To contribute to this effort, the NWCS team has been researching hemp to assess its feasibility as a crop in the northeast. Agronomist Dr. Heather Darby and NWCS Hemp Research Specialist Laura Sullivan have been working toward producing clothing from their industrial hemp trial fields at Borderview Research Farm for the past five years, overcoming many obstacles and challenges along the way. The greatest barrier wasn’t growing the crop, but bridging the gaps in the regional and domestic textile supply chain that turns raw fiber from small growers into value-added products. Ultimately, the NWCS team had to adapt and gain new skills to meet this challenge.

Step 1: Growing

The story of the sweater vests began when the NWCS team planted hemp trials at Borderview Research Farm in May 2024. Hemp grows quite tall and outcompetes weeds quickly if well-established. Generally, fiber hemp is harvested between 60 and 100 days. Depending on genetics, plants grown in Vermont can surpass 3m in height within this time frame. Fiber hemp is typically ready for harvest as soon as the first male flowers emerge, which can occur as early as July. Fiber hemp left longer will eventually go to seed and can be harvested for grain.

Step 2: Retting

Field Retting

Hemp is a bast fiber, meaning the fiber runs the length of the stalk, (as opposed to a plant like cotton, where the fiber is extracted from the husk of the seed). All bast fiber plants, like hemp and flax, must undergo a retting process to liberate the fiber from the inner woody core of the stalk, known as the hurd. In short, the goal of the process is to remove the natural glues and gums that entrap the fiber tissue. Watch this short video for a clear demonstration from Laura Sullivan. There are multiple ways to achieve this, including field retting, chemical retting, and water retting. For this project, we wanted to observe the impact of two different retting methods on end-use for textiles. We began our inquiry by field retting some of the trials in early October. This involved cutting the stalks, lining them up on the ground in a neat swath, and leaving them to become a feeding ground for bacteria and microorganisms with a taste for pectin and lignin. Field, or dew, retting is the most widely practiced natural method of hemp retting.How do you know if hemp is fully retted? (YouTube video)

Winter Retting

The hemp that was not cut down for field retting in the fall was left standing in the field to weather the winter. Unlike field retting, which is a microbial process, winter retting is better described as a mechanical one. It is the undulation of the temperature fluctuating between freeze and thaw that works to mechanically release the fiber from the natural glues in the stalk.

This trial was the first winter retting study conducted in the modern history of the Northeast. The experimental design involved harvesting fiber hemp stalks at one-month intervals from December 2024 through April 2025. Upon each harvest timing, sampled material was photo-documented and subject to physical and chemical analysis. An electron microscope was also utilized to observe changes in fiber composition at the cellular level. To learn more about winter retting, watch this video where Laura Sullivan gives her final thoughts on the last winter-retted hemp harvest date of 2025.

Watch the final harvest date for winter-retted hemp (YouTube video)

Step 3: Processing

After wrapping up fieldwork and data collection in mid-April of 2025, the team looked ahead to the next challenge: processing the fiber. Ideally, at this point in the process, we would deliver our raw material to the local scutching mill ahead of spinning. There, they would perform a three-step process turning stalks into spinnable fiber, with hurd as a value-added byproduct of the process. Unfortunately for us, no such mill currently exists in the United States, so we became one.

Decorticating, Hackling, and Carding

To do this, the team used a small Formation Ag decorticator (Figure 6) to crush each stalk, separating the woody hurd from the strong, flexible bast fibers. The broken fiber was then beaten by hand with a simple wooden knife (which happened to be at least one hundred years old!) to remove any lingering hurd in a middle step called “scutching.” Finally, we used a mechanized hackler (Figure 7), purchased from our partners at Taproot Fibrelab in Nova Scotia, to comb the scutched fiber bundles into fine spinnable fibers in a process called “hackling.” The purchase of the hackler was made possible with funds from the USDA NIFA Sun Grant Program. Watch this video to see the decorticator and the hackler in action at Borderview Research Farm.

See the carder and hackler in action! (YouTube video)

With the scutching complete, ideally we would take our clean line fiber (Figure 9) to the local wet-spinning mill to be spun into a 100% hemp yarn. Unfortunately, there is no wet-spinning mill in the entire western hemisphere, and if you want to commercially produce a hemp yarn in the U.S., you have to blend it with cotton or wool. This is because our existing domestic spinning infrastructure is geared toward shorter staple-length fibers, such as cotton or wool, and cannot manage a fiber like hemp with regular lengths of 1m or greater. Therefore, to suit our regional manufacturing capabilities, we had to perform two more steps before we could see our hemp spun into yarn.

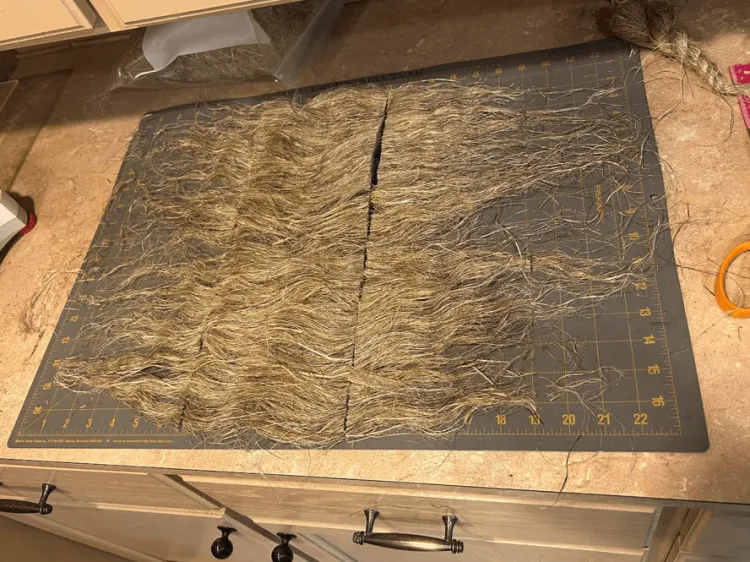

“Woollenizing”

The hemp needed to be blended with wool to make it suitable for yarn. To “woollenize” the hemp, we cut the long fibers to six-inch lengths to match the staple length of the wool that would be blended in. Then we rigorously carded the fiber three times with a hand-crank carding machine until the fibers were combed and aligned into several fluffy bats. The purpose of this process was to retrofit the hemp fiber to behave more like wool fiber. This was a team effort! Sixteen pounds of “woollenized” fiber later, and we were ready to hand it off for the next step in processing.

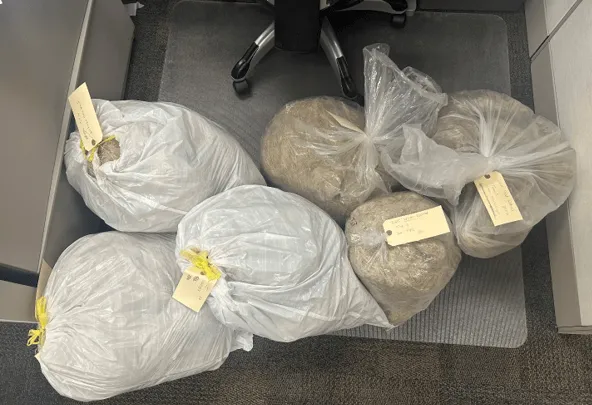

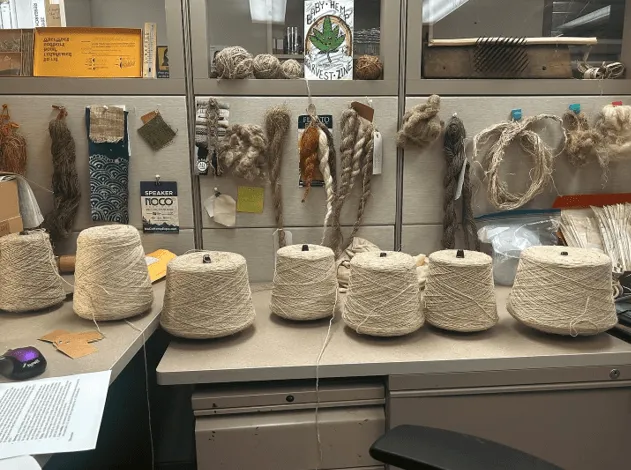

Step 4: Spinning and Sewing Local Partnerships

Next, we brought our woollenized hemp fiber to our partners at Battenkill Fibers for spinning. Stepping into unprecedented territory, we worked with Tim Holt at Battenkill to create an experimental design to find the hemp best suited for fiber processing and spinning. The spinning trials consisted of six different treatments. Two of the treatments utilized field retted fiber from our 2024 growing season, and the remaining four used our winter retted material. Four of the treatments blended our hemp with wool at a ratio of 70% wool to 30% hemp. The other two treatments prototyped alternative ratios of 80:20 (wool:hemp) and 60:40 (wool:hemp). The wool utilized was Corriedale from the Finger Lakes region of New York. We put together a short video about our trip to Battenkill Fibers. Watch our experience at Battenkill Fibers.

Learn more about our experience at Battenkill Fibers (YouTube video)

The resulting yarns represent the first all-local and commercially spun hemp yarns in the modern history of the Northeast, and the entire process, from stalk to spool, occurred within the bounds of Vermont and New York.

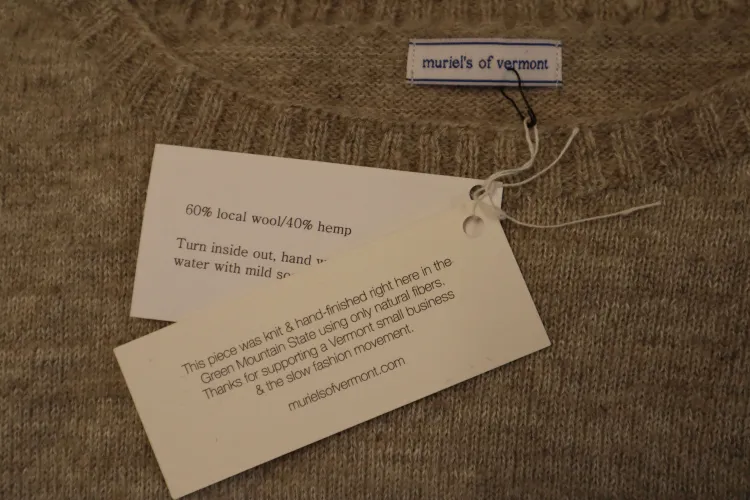

Our story could have ended there, but in a state with highly skilled people, such as Vermont, we were lucky to be situated within 20 miles of a knitwear designer already familiar with all things local fiber. Muriel’s of Vermont is a mother-and-son team designing “farm to cable” knitwear on three Japanese knitting machines in their North Hero studio. We knew they were a perfect partner for us, not only because of their proximity to the farm, but also because they were already making sweaters using similar yarn blends featuring local wool and imported hemp. Now, we would be creating the ultimate local garment using regional wool and local hemp. The NWCS team, Battenkill Fibers, and Muriel’s of Vermont were all invested in seeing what local hemp could do. The resulting garments did not disappoint.

Reflections and Conclusions

With the help of our many partners and collaborators, we created three wool:hemp sweater vests. The cream sweater vests are slightly cropped with a boxy fit and feature a V-neck design. The garments are soft to the touch with that bit of roughness that can be expected from wool and natural fibers. If you look closely, you can see the tan hemp fibers within the vests. These designs are very wearable and offer warmth without too much weight. They are the kind of piece that you could have in your closet for years to come.

The consensus among our NWCS staff and the Muriel’s of Vermont team is that the 70:30 wool:hemp blend produced a softer product. Cyrus Brooks, knitwear designer at Muriel’s of Vermont, also noted that their Japanese knitting machines had a hard time working with the 60:40 wool:hemp blend, citing that “the blend isn’t very forgiving,” Cyrus said. “It’s strong until it breaks. It doesn’t really stretch.” Some yarn, like the 60:40 blend, is less consistent in size throughout and has many clumps, or “slubs” as they are called. Slubs trigger stoppages in the knitting machines, which can make it difficult to process yarn with inconsistencies.

In terms of winter retted or field retted fiber, we had success in integrating both into our regional infrastructure and have determined that both are suitable for textile use in our climate. In this round, we yielded a finer product with field retted fiber, but we are interested in building upon our winter retting inquiry with more experimentation.

This work represents a new paradigm of possibility for agriculture in Vermont. We are very grateful for the support we received from the Agriculture and Food Research Initiative (AFRI) Critical Agriculture Research and Extension (CARE) program, project award no. 2023-69008-39277; and the Sun Grant Program, project award no. 2020-38502-32916 (3TD372-PSU), from the U.S. Department of Agriculture’s National Institute of Food and Agriculture. Many additional thanks to Roger Rainville, Travis Driver, Steve Kostell, Chris Callahan, Giovanna Sassi, Andrew Chamberlin, Heather Darby, and the whole Northwest Crops and Soils team for their perseverance in seeing this work through to completion. If, like us, you have now developed an insatiable thirst for Vermont fiber, visit our YouTube page for more stories and behind-the-scenes footage from the project.

References

Chen, X., Memon, H. A., Wang, Y., Marriam, I., & Tebyetekerwa, M. (2021). Circular Economy and Sustainability of the Clothing and Textile Industry. Materials Circular Economy, 3(1), 12. https://doi.org/10.1007/s42824-021-00026-2