Evaluating Hay Crop Silage Inoculants for Use in Organic Systems

When we harvest hay crop silages, naturally occurring bacteria present on the forage are responsible for completing the fermentation process we rely on to preserve the silage. During fermentation, bacteria take sugars in the forage and convert it into organic acids that acidify the material and preserve nutrients.

Goals for good silage fermentation:

1. Rapid reduction of oxygen and pH

2. Preserve nutrients & dry matter

3. Create an undesirable environment for yeast & mold growth

4. Provide stable & consistent feed

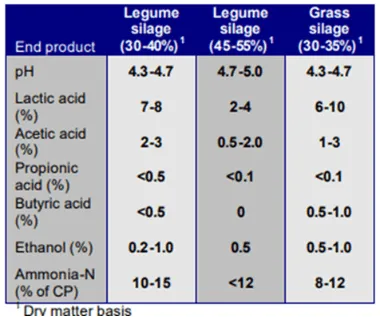

End products resulting from silage fermentation:

Lactate – drives acidification & pH reduction

Acetate – antifungal properties; milk fat synthesis

Propionate – antifungal properties; glucogenic in rumen

Butyrate – fermentation from spore forming bacteria; animal health issues

Ethanol – associated with yeast fermentation

Ammonia – results from proteolysis & nutrient breakdown

Analysis Reports. Limin Kung & Randy Shaver.

Depending on how many and which bacteria are present, this process could yield very different results. Using an inoculant can ensure sufficient population and type of bacteria are present to adequately reduce silage pH or stabilize the silage during feed out.

There are two main types of bacteria used in silage inoculants: homofermenters and heterofermenters. Homofermenters are those that convert the sugars in the forage to lactic acid. Common homofermenters used in silage inoculant produces include Lactobacillus plantarum, Pediococcus spp., and Enterococcus faecium. Because lactic acid is a strong acid that can reduce the pH significantly and quickly but does not inhibit yeast and mold growth very well, products containing homofermenters are typically used where preserving the forage as quickly as possible and reducing dry matter losses are the goals.

In contrast, heterofermenters can make several different products during fermentation; they may make lactic acid, acetic acid, or other products. Because acetic acid is a weak acid but a better inhibitor of spoilage organism growth, heterofermenters are used when silage aerobic stability is the priority. Lactobacillus buchnerii is a common heterofermenter added into inoculant products to support silage stability during feed out.

Products can contain one or both of these types of bacteria. They come in dry granular or water-soluble formulations with specific applicators that mount to the bailer or chopper. There are also several products approved for use in organic systems. More information on silage inoculants can be found at the resources below.

University of Vermont Extension Silage Inoculants Factsheet

University of Wisconsin Extension Silage Inoculants Factsheet

Despite the availability of organically approved products, using silage inoculants on organic farms is not very common. To gain more information on the use of organic inoculants, we are initiating several research trials this season.

Trial 1- Evaluating the efficacy of organically approved silage inoculants

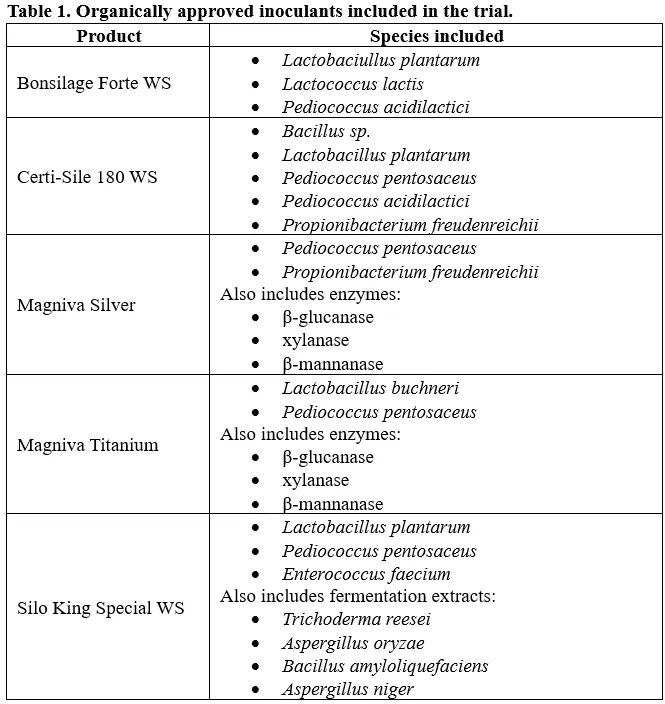

The first trial will compare the efficacy of five different organically approved silage inoculants and a no inoculant control in grass silage. The silage inoculants being used are listed in table 1.

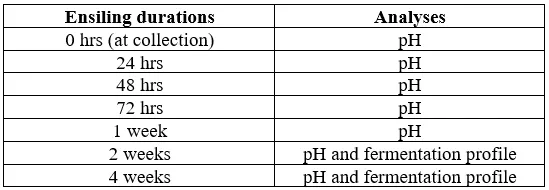

We mowed an existing stand of orchardgrass and applied each inoculant product per their labels to different sections of the windrows using a small sprayer just before chopping. Material was then chopped into a forage wagon where material from each section was segregated and collected. Approximately 250-275 grams of material were then placed into vacuum seal bags and sealed to simulate bunk packing. Samples were kept in black plastic totes at ambient temperatures until removal to obtain the ensiling durations outlined in Table 2 at which point they were frozen to stop fermentation or other biological activity. Samples will be analyzed for pH and fermentation profiles as per Table 2.

Trial 2: Silage inoculant efficacy under varying dry matter conditions

Another trial will be conducted this year using the same existing stand of orchard grass that will be mowed and this time wilted to three different dry matter contents, representing forage that is too wet, ideal, and too dry. We will then apply one of the inoculant products at three different rates representing the rate according to the label, 2x the rate on the label, and 3x the rate on the label. Inoculant application, sample vacuum sealing, and sample storage and retention time will be the same as described for Trial 1. Stay tuned for results!