The resistance drill allows

for quantification

of section loss in decayed timbers.

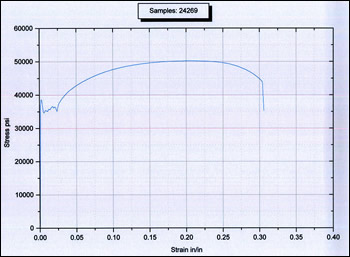

Yield strength of iron samples tested

exceeded values found in period handboks.

![]()

BREEDING BARN - MATERIALS CHARACTERIZATION

Conditions survey of the Barn indicated that more detailed examination was necessary to determine the quality and condition of several of the iron structural elements, and to determine the extent of the deterioration in several of the timber elements. The team was most concerned with the capacity of unbraced trusses in each of the major dormers and with the condition of several of the valley rafters. Valley rafters exhibited varying levels of decay, and in some cases had dislodged from their original positions at rafter apexes.

A metallurgist was brought in to characterize the wrought iron used in struts and tension elements. Samples were obtained from fabric that had been previously demolished. The samples were large enough for conducting tension tests (ASTM E8) of the iron, in order to establish reasonable design values for the material. Small portions of each sample were retained for metallographic characterization. Analysis indicated a low-carbon material; the closest SAE-AISI designation is 1005.

In order to quantify the extent of deterioration in decayed timber elements, a wood scientist assisted with a detailed evaluation of decayed timbers identified by the survey team. Quantification entailed resistance drilling of decayed timbers, using the IML-RESI System. Resistance drilling is a quasi-nondestructive technique for determining the relative density of wood, identifying discontinuities and quantifying the extent of section loss in the process. The process was exceptionally useful in evaluating valley rafter timbers, where installation of reinforcing steel channels (sometime in the 20th century) on either side of each timber prevented direct examination in most cases. Of the twelve timbers examined, four were found to have substantial section loss due to decay. Results of resistance drilling tests were expressed graphically and in tabular form, indicating the extent of section loss at each of the drill sites. By pinpointing areas of loss, resistance drilling will permit detailed design of timber repairs prior to dismantling the affected portions of the building, helping to reduce the number of inappropriate decisions made in the field.

Project Specifics

- Materials Characterization

- Load Test

- Laser Scanning

Links

Contact

To find out more about current projects or future field study opportunities, please contact:

Douglas Porter

School of Engineering

University of Vermont

341 Votey Hall

33 Colchester Ave.

Burlington, VT 05405-0156

(802) 656-4027 or

(802) 497-0689

Douglas.Porter@uvm.edu