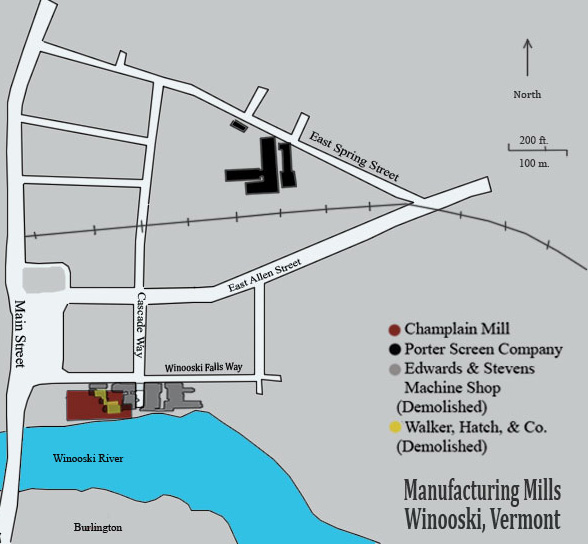

Manufacturing in Winooski, Vermont (east of Main Street)

By Ashley Phillips

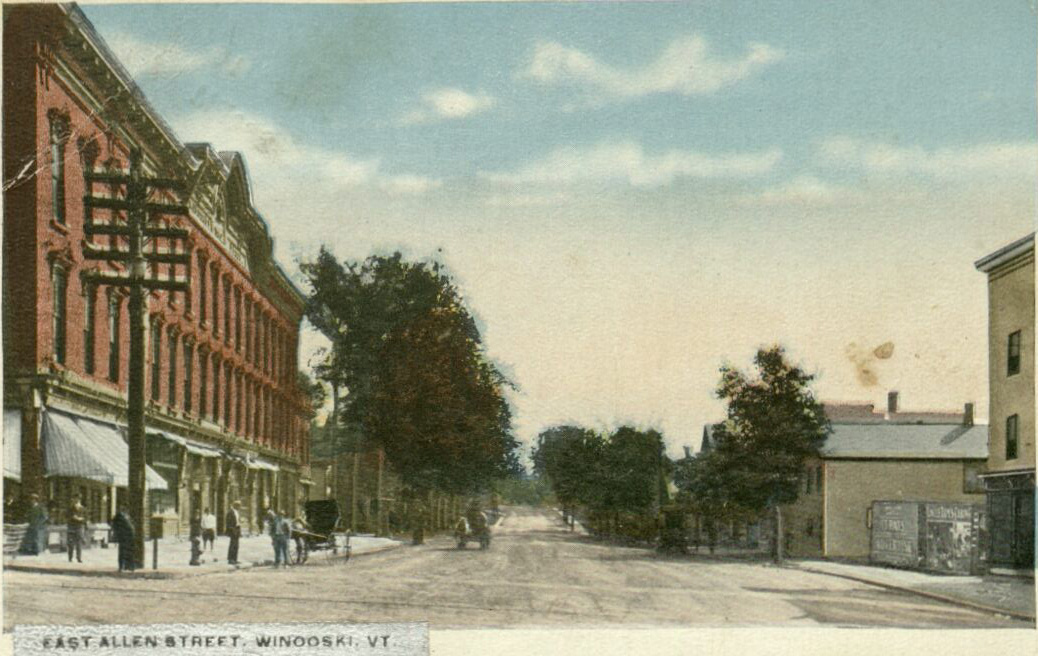

In the mid-19th century, Winooski, Vermont was home to some of the state's largest and most innovative manufacturing companies. Located just north of Burlington (and part of the town of Colchester until being incorporated as a separate city in 1922), Winooski offered mill owners ample land, railroad access, and most importantly, water power from the Winooski River. Whether manufacturing fine wools or state of the art machinery, the mills and factories in Winooski helped shape Vermont's industrial heritage.

Area Timeline

1840- Edwards and White open machine shop on East Canal Street in Winooski, Vermont

1840s- Queen City Brick Co. established in Winooski

1857- Edwards and White machine shop destroyed by fire

1857- White dies, Edwards partners with former employee Alonzo Stevens

1859- Edwards and Stevens build new shop

1866- Edwards and Stevens Expand the machine shop

1874- Walker Hatch Co opens in Burlington, Vermont

1885- Walker Hatch Co moves business to new building on East Canal Street in Winooski, Vermont

1885- Porter Screen Company formed in Burlington

1887- Walker Hatch Co insolvent, bought by Winooski Lumber Company

1893- Porter Screen Company moves to East Canal Street

1895- Porter Screen Company relocated to East Spring Street in Winooski, Vermont

1898- Fire destroys Edwards and Stevens shop

1900- Fire destroys Porter Screen Company shops

1901- New Porter Screen warehouses built

1909- Queen City Brick supplied foundation materials for Champlain Mill

1912- American Woolen Company opens Champlain Mill on East Canal Street

1917- Stevens Machine shop sold to American Woolen Company

1927- Winooski River floods

1952- Porter Screen Company closes

1954- Champlain Mill closes

1981- Champlain Mill rehabilitated for offices, retail shops, and restaurants with historic preservation tax credit support

2011- Champlain Mill rehabilitated again with historic preservation tax credit support

Champlain Mill

The Champlain Mill in Winooski, Vermont was completed in 1912. In its 100 year history, Champlain Mill was transformed from a productive woolen mill, to a warehouse, to a vacant and neglected building, to an urban shopping mall, and most recently, to office space. Each incarnation has been a reflection of economic status of the surrounding city of Winooski, Vermont and the mill has been referred to as a "barometer…to measure the ebbs and flow of Winooski fortune." 1

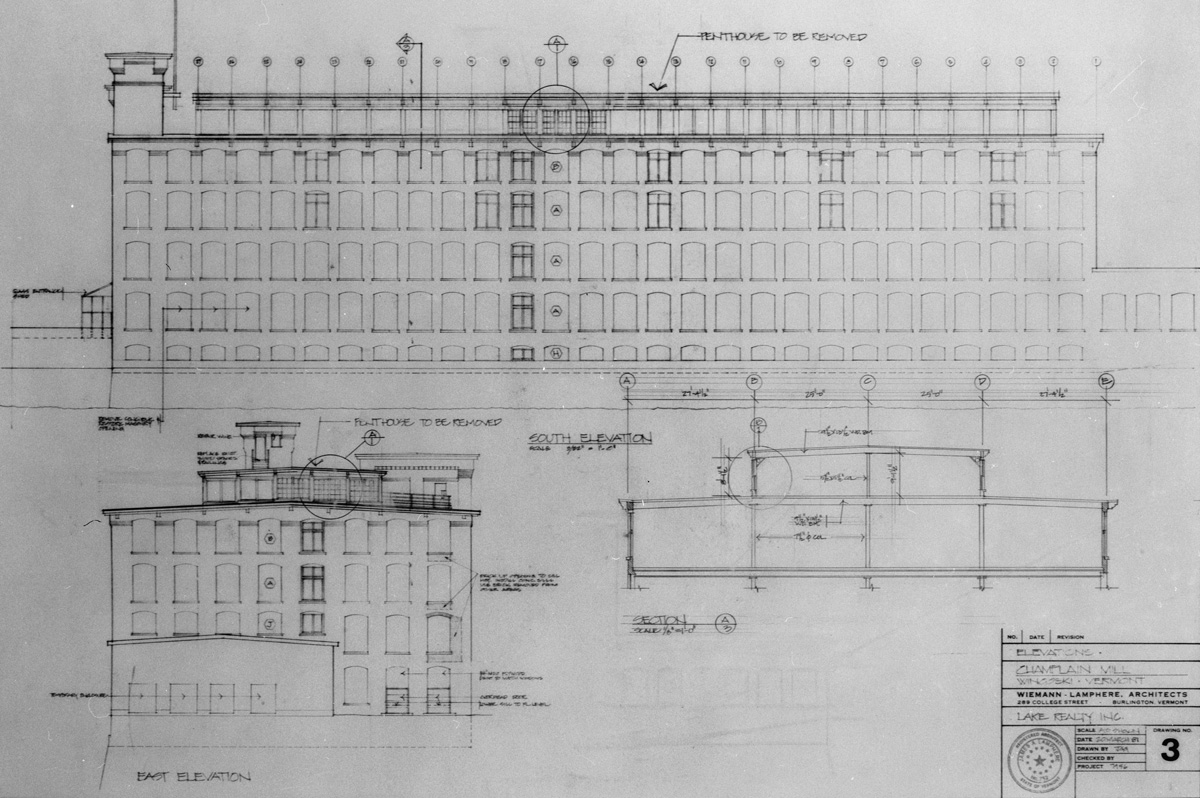

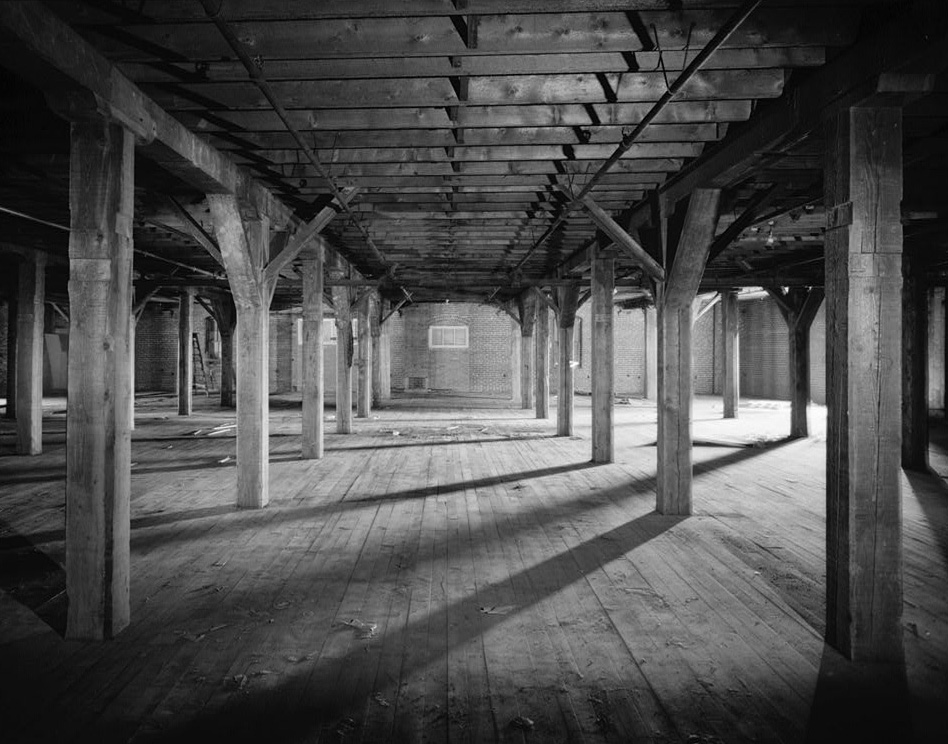

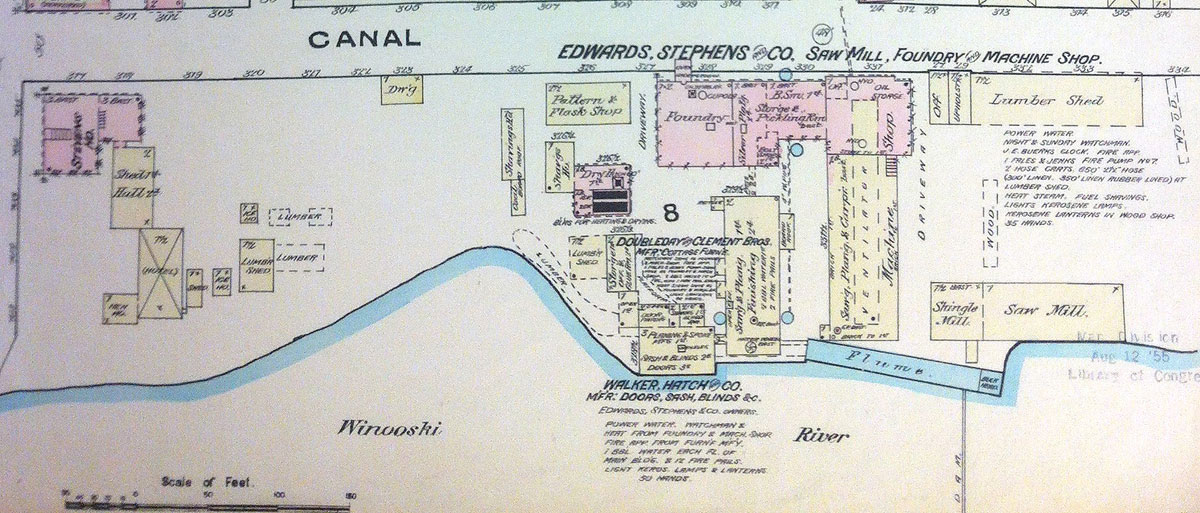

The Champlain Mill was part of a 1909 expansion plan of the American Woolen Company. General Agent Whitney purchased land next to Edwards and Stephens Machine Shop, between the banks of Winooski River and East Canal Street, which included rights to 3/5 of the water power supplied from the upper dam. The new building, known at the time as Mill Number Four, was completed in 1912 and was used primarily for spinning worsted woolen cloth. At 156,000 square feet, it was the largest mill of the Woolen Company complex, with five stories of operations and the capacity to employ 500 workers. The village residents and town planners, eager to see the mill succeed, granted the American Woolen Company's requested five-year tax exemption for the mill, effective April 1, 1911. Construction began in the winter of 1909, using brick from Drury Brick and Tile Company out of Essex, and crushed stone from the Queen City Brick and Stone Company in Winooski. The labor contract went to Massachusetts based E. W. Pitman Company. A temporary cofferdam was constructed to facilitate the construction of the south river wall, followed by 1.5 million pounds cement poured to construct the 375 ft. long and 28 ft. high southern river wall and foundation of the mill.2

Power for the mill was harnessed from the Winooski River. The American Woolen Company used sixty percent of water power from the upper dam of the Winooski just for the Champlain Mill. A 500 horse-power turbine, fabricated by the Stevens Machine Shop, was installed under a 17 foot head and located in the mill's power house on the east end of the building. The water wheel generated enough power to run all five stories of mill operation.3

Construction of the mill hallmarked the economic prosperity Winooski was experiencing. Along with the rest of the United States, Vermont's mill town were seeing a boom in industry following the First World War. New technology flourished, and American Woolen Company's new mill was said to be "one of the world's best equipped." 4 Over the next decade, that would prove true. Mill operations continued to expand, and American Woolen Company was determined to use the best technology to ensure maximum efficiency. In 1916, 78 new looms were added to the enterprise, bringing the number of operational looms up to 600. All five stories, including the clerestory were used at full capacity. The mill produced piece-dyed worsted fabric, silks, and yarns for serging, weaving, and knitting. A 1926 Sanborn Insurance map noted the manufacturing layout: The 1st floor was used for weaving, the 2nd floor for stock and weaving, spinning and wool storage occupied the 3rd floor, and the 4th floor housed the spooling machines.5

In 1927, the Winooski River flooded, causing millions of dollars in damage across the state. Rising waters inundated the Champlain Mill, fully flooding the basement, and reaching as high as the second floor. This event marked the beginning of the decline of Vermont's woolen industry. The flood damage was followed by the crash of the stock market and the Great Depression that gripped the country during the 1930s. World War Two provided a brief upswing in the demand for wool in the 1940s, but demand fell sharply by the end of the decade. In 1954, Textron, who had purchased American Woolen Company, closed all the woolen mills in Winooski, including the Champlain Mill.6

Shortly after the woolen company closed, Champlain Mill was purchased by the Winooski Reality Company. IBM, General Electric, and a paper box manufacturer rented space in the mill, and it was frequently used as a warehouse through the late 1950s and into the 1960s. In the 1970s, the City of Winooski purchased the building as part of a federal Model City and Urban Renewal project. However, Champlain Mill was not included in the city's rejuvenation plans, and the mill sat empty for much of the decade until it was purchased by Raymond Pecor in 1978. Pecor planned to rehabilitate the old mill into a commercial center. The building had suffered greatly during its decade of vacancy; windows were broken, brickwork was deteriorated, and leaks in the roof and roosting pigeons had caused extensive damage to the interior. Renovations began in 1980. A new roof resulted in the removal of the clerestory due to structural load restrictions on the existing timber supports. Pecor replaced all of the windows with two-over-two energy efficient glass panes, and cleaned and repointed the exterior brickwork. The interior was also heavily remolded to accommodate offices and retail space, but much of the interior historic skeletal framing was left intact.7

The mill was reopened for business in September 1981. Several large businesses, including the Vermont Student Assistance Corporation (VSAC) took residence in the office suites of the upper floors. Retail business in the basement and ground floor, came and went. The longest tenant was Waterworks, a restaurant located in the mill's former powerhouse. When VSAC moved out in 2000, the building, along with much of downtown Winooski, was once again nearly vacant.8

Today, the mill is a beacon for the revitalization Winooski has been experiencing. In 2011, MyWebGrocers purchased the building, and using federal and state tax credits, have done another renovation on the 100 year old mill. Company head Jerry Owner replaced the 1980s two-over-two windows with six-over-twelve paned windows, installed a new roof, and updated the HVAC and safety systems. MyWebGrocers occupies the fifth floor of the building, with other companies and agencies on the lower floors.9

Notes (Champlain Mill)

2. "New Winooski Mill Assured", Vermont Watchman and State Journal (Montpelier, VT), Oct. 28, 1909; "Chittenden County Winooski", Burlington Free Press and Times (Burlington, VT), Nov. 11, 1909; "Vermont Water Power," Burlington Free Press and Times (Burlington, VT), Dec. 22, 1910.

3. Vermont Watchman and State Journal (Montpelier, VT), Oct. 28, 1909.

4. James Lamphere, "The Champlain Mill: Adapting Architectural Features," The Mills at Winooski Falls: Burlington and Winooski, Vermont, Illustrated Essays and Oral Histories, ed. Laura P. Krawitt (Winooski, Onion River Press), 178-179; Sanborn Fire Insurance Company, Sanborn Fire Insurance Map; Winooski, 1926 (New York: Sanborn Fire Insurance Company, 1926).

5. "600 New Looms at Winooski," Middlebury Register (Middlebury, VT), Jan. 28, 1916; Louis W. Steponaitis, Jr. "The Textile Industry in Vermont, 1790-1973: Its Development, Diffusion and Decline" (Master's Thesis, University of Vermont, 1975) 98,112,117.

6. Ray Pecor, "Why I Purchased the Champlain Mill," The Mills at Winooski Falls: Burlington and Winooski, Vermont, Illustrated Essays and Oral Histories, ed. Laura P. Krawitt (Winooski, Onion River Press), 178-179.

7. Dan Higgins, Vagrancy, Art and Transformation: Winooski, 1969-2005 (Winooski, VT: The Photo Lounge, 2006), 41.

8. "MyWebGrocer: Bringing New Life to an Old Building," Vermont.gov, accessed Oct. 22, 2013, http://accd.vermont.gov/strong_communities/case_study/mywebgrocer.

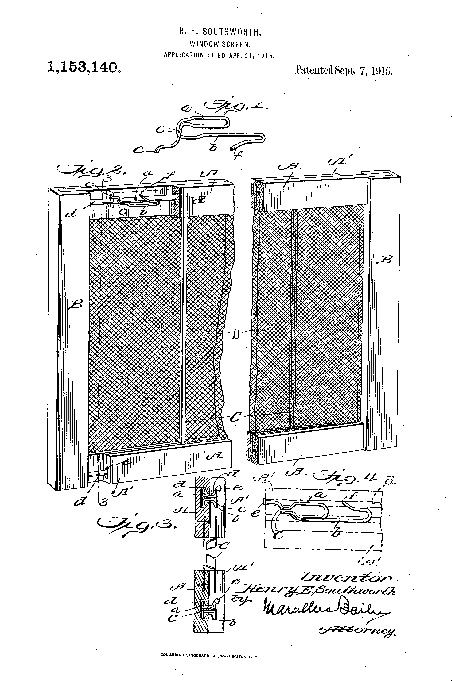

Porter Screen Company

The Porter Screen Company expanded from a small one-man enterprise to become one of the largest industries in New England. Former factory employee and inventor, T. "Pele" Limose proudly stated, "Indeed, in screens the company fed the world." 1 And for the first couple decades of the twentieth century, that was true. The Winooski based screen company was the nation's leader in wire screen production.2

The company was founded in Burlington, Vermont in 1885 by inventor E. N. Porter who had patented some successful door hardware. The company operated for two years on the corner of North Winooski Avenue and Pearl Street, and at a second location near the lake front before moving to Winooski in 1893. Porter set up shop near the Edwards and Stevens Machine Shop on East Canal Street along the Winooski River.3 Operations grew quickly, and the Porter Screen Company outgrew its location on East Canal Street. Porter relocated his business to a site between East Spring Street and the main line of the Central Vermont Rail Road tracks in 1895. The factory continued to expand over the next few years, and by 1899 included two manufacturing buildings, three storage facilities, an office building, a lumber yard, and several out buildings.4

But the prosperity was short lived. The next year fire swept through the factory, injuring two employees, causing a loss of $200,000, and forcing the unemployment of 200 workers. The fire began in the paint shop, and quickly became uncontrollable when it ignited oil barrels and other combustibles. The Vermont Watchman referred to the scene as "The greatest fire that ever visited Winooski." 5 The factories automatic sprinkler system, 10,000 gallons of water, and three hours of firefighting efforts could not combat the flames. The factory was burned to the ground. With an insurance policy of $180,000, the company was forced to downsize and move back into rental space at the Stevens Machine Shop on East Canal Street while a new factory was built at East Spring Street.6

The new plant, fully operational by 1901, incorporated a total six acres of land. Porter purchased additional land between Allen Street and the train tracks, acquired several existing homes to serve as employee housing, and purchased a train car barn from the Trolley Company.7

A 1910 Burlington Free Press article erroneously reported the Porter Screen Company to be closing its Winooski plant and moving operations to Trenton New Jersey. Sources cited rising transportation and raw material costs to be the driving factor behind the move. The truth however, was a New Jersey company, Wire Cloth Co., purchased the company after taking note of their large sales numbers throughout the northeast. The new owners retained Porter's sales manager, H. A. Way, and maintained the factory in Winooski after reincorporating the business as Porter Screen Manufacturing Company.8

Business continued to boom for the Porter Screen Company. Fine woods were imported from the Pacific states, southern states, and harvested locally, to create its line of wood wares and doors. The company shipped an average of 30,000 wood doors and 100,000 window and door screens every day, enough to fill 10 to 13 box cars that shipped throughout New England, New York, and Pennsylvania. The company even filled orders from as far away as New Zealand, South Africa, and Holland. In 1911, Porter Screen bought out the Roll-away Screen Company of South Easton, Massachusetts and moved all manufacturing of rollaway screens to its Winooski location, in a newly constructed two-story brick building.9

In 1913 Manager Harry A. Ways purchased the company from the New Jersey Wire Company and reinstated the original company name—Porter Screen Company. Ways restructured the company to focus on the most marketable wares: stock screen doors, combination doors, and window screens, along with a line of wooden wares such as ironing tables and skirt boards. Ways sold the made-to-order screen department to Robbins Manufacturing Company, and discontinued the Roll-Away Screen department in 1916.10

Like many businesses in Winooski, the flood of 1927 had negative effects on the Porter Screen Factory. The company had long since moved from the river bank, but its business was reliant upon Vermont's rail system, much of which had been swept away in the flood waters, to transport material and products to and from the facility. At a heavy cost, Ways rented trucks to continue transportation of goods to and from the factory for seven months while the Vermont rail system was waylaid.11

In 1940, H.A. Ways died and left the screen company to his three children. His son, Henry bought out his siblings two years later and ran the business as its sole proprietor. In a forward thinking move, Henry Ways purchased local timber land and took a contract to build army cot beds. By the early 1950s, demand for wood doors and other wooden wares greatly declined, in favor of more modern metal doors and screens. In 1952, Ways decided to close the manufacturing plant and converted the complex of buildings as warehouses, which he leased out until his death in 1957.12

Since the closure of the Porter Screen Company, the complex of buildings served various functions over the years, including housing a beer and wine distribution company, day care facility, and since 1980, a city run senior housing facility. The Porter Screen Company office and warehouses were listed on the National Registry of Historic Places in 1979.13

Notes (Porter Screen Company)

2. Arthur F. Stone, Vermont of Today, With its Historic Background, Attractions and People, (NY: Lewis Historical Publishing Company, Inc. 1929), 772.

3. Ibid; Sanborn Fire Insurance Company, Sanborn Fire Insurance Map; Winooski 1894 (New York: Sanborn Fire Insurance Company, 1894).

4. Sanborn Fire Insurance Company, Sanborn Fire Insurance Map; Winooski 1899 (New York: Sanborn Fire Insurance Company, 1899).

5. Vermont Watchman and State Journal, (Montpelier, VT), Nov. 28, 1900.

6."Vermont Local News," Burlington Free Press (Burlington, VT), July 28, 1898; "Fire Loss of $200,000 at Winooski," Vermont Phoenix (Brattleboro, VT), Nov. 23, 1900; Vermont Watchman and State Journal, (VT), Nov. 21, 1900.

7. Sanborn 1904; Limose.

8. Limose; "Winooski Loses a Big Industry," Burlington Free Press and Times (Burlington, VT), Dec. 29, 1910.

9. Limose; Burlington Free Press and Times (Burlington, VT), Oct. 12, 1911.

10. Limose.

11. Ibid.

12. Look Around Winooski, VT 1972, (Burlington: George Little Press Inc.), 11.

13. Manning's' Burlington Winooski and Essex Junction Directory (Springfield, MA: H.A. Manning Co., 1984), 510.

Walker, Hatch and Company

Walker, Hatch, & Co., manufacturers of stairs, furniture and doors started their business in the mid-1870s, and began expanding their company with the purchase of the Burlington Spoke Company in 1883. Within two years, the company secured enough investments to build a new shop on East Canal Street, next to Steven's Machine Shop in Winooski. The new building was 200 feet long, 50 feet wide, and three stories high. Plans also included construction of a large store house, shavings house, office, and a brick boiler house. Owners David Walker and Frank Hatch hoped to be able to employ at least a hundred men at their new location.1

Problems for the company began shortly after construction was complete. Walker and Hatch were unable to pay their investors for the debts they accrued for construction. Creditors began looking over books by November 1886. Less than a year later, the company was deemed insolvent by the courts, with liabilities totaling about $35,000. The land and buildings were sold to recoup the debt, and was subsequently purchased by Winooski Lumber Company in 1887.2

Notes (Walker and Hatch)

2. "The Walker Hatch Failure," Burlington Free Press (Burlington, VT), Nov. 18, 1886.

Queen City Brick Co.

Queen City Brick was a family company. Owned by several generations of Winooski's prominent Graves and LeClair family, the brick yard supplied stone and brick for over 100 buildings in the Winooski area, including the iconic Winooski Block.

The original brick yard was founded by Francis LeClair, Jr. who emigrated from Quebec, Canada in 1828 when he was ten years old. His family settled in Colchester, Vermont and started a small farm in the area that would become Winooski. Through his various endeavors, Francis LeClair grew into a notable citizen of Winooski; He operated two brick yards, one on Mallets Bay Avenue, and another on Colchester Avenue. He also ran a grocery store, served two terms in the Vermont legislature, and was a leader in the Catholic community of Winooski.1

By 1849, LeClair's brick yards were putting out 1,800,000 bricks annually and employed 26 men, netting a $12,000 yearly income for Leclair. Over the next 25 years, Leclair built 75 brick houses in Winooski and ten in Burlington. His houses were small and simple, designed to give people with lower incomes an opportunity to own an affordable home. LeClair and his company also built public buildings. Of note are the St. Francis Xavier Church and the Winooski Block, which he built with Charles Lafountain.2

In 1886, the elderly LeClair sold his business stocks and rented the brick business to his son in law, Aldophus A. Graves. When LeClair died in 1889, he willed his estate, worth approximately $30,000, to his son-in-law and daughter. A.A. Graves used the money to purchase the brick yards, and incorporated them into Queen City Brick Works in 1904. Graves ran a successful business in brick and stone, and was noted as being the largest brick manufacturer in Vermont. Graves set up Queen City Brick Work's office and store front in the Winooski Block and operated the company until his death in 1904.3

Graves' three children inherited the brick business and reincorporated the company in 1904 as Queen City Brick and Stone Company. The oldest son, Frank L. Graves served as the company president. That same year, the brick company produced 300,000 bricks, 1000 tons of building stones, and 2,000 tons in crushed stones for roadways. Frank Graves oversaw the company's largest endeavors, including stone for the Champlain Mill foundation, brick and stone for Fort Ethan Allen roadways.4

Notes (Queen City Brick Co.)

2. Ibid.

3. "Valuable Property for Sale Cheap," Burlington Weekly Free Press (Burlington, VT), Apr. 28, 1868; Arthur F. Stone, Vermont of Today, With its Historic Background, Attractions and People," (NY: Lewis Historical Publishing Company, Inc., 1929); Burlington City and Winooski Directory (Burlington: Free Press Printing Co.), 434.

4. Stone, 149, 668; "Chittenden County Winooski," Burlington Free Press and Times (Burlington, VT), Oct. 22, 1903; "Chittenden County Winooski," Burlington Free Press and Times (Burlington, VT), Oct. 28, 1909.

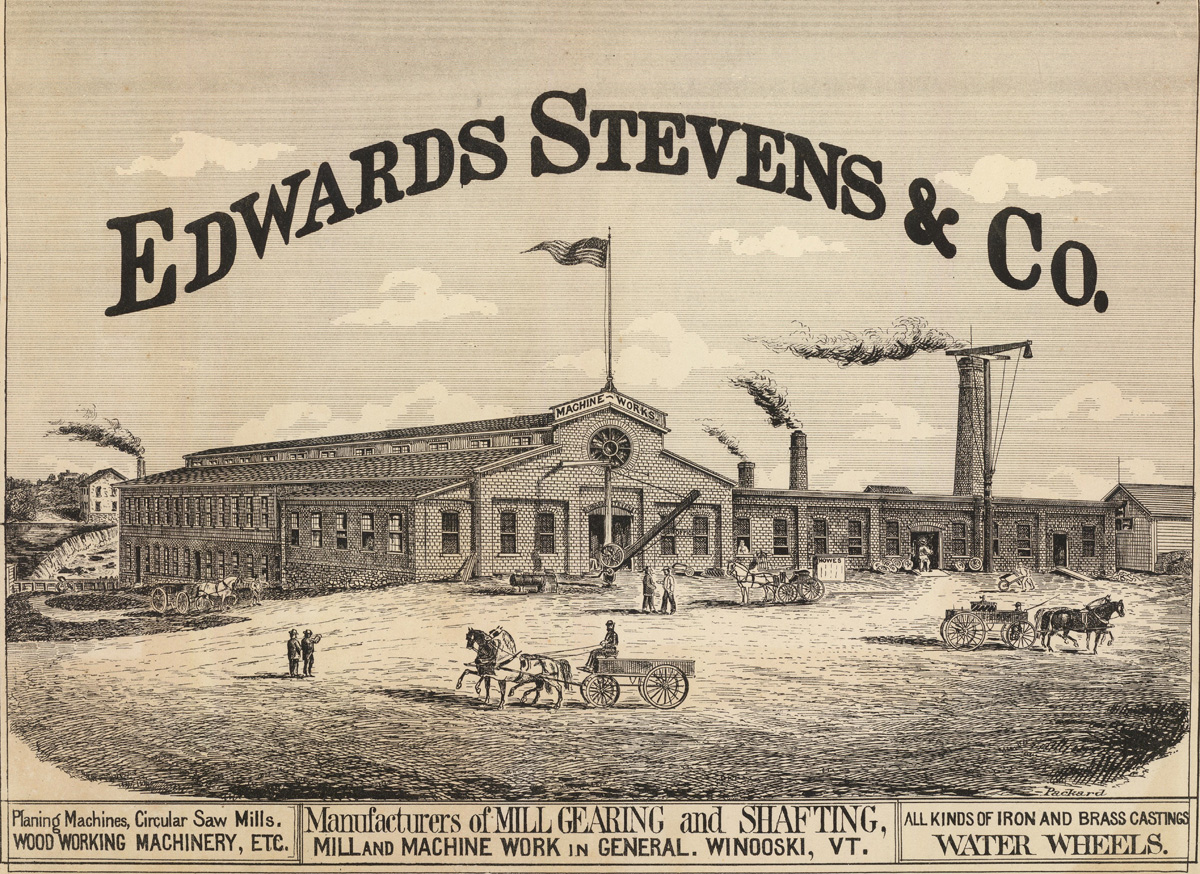

Edwards & Stevens Machine Company

In the mid-19th century, Avery B. Edwards established a machine shop along the Winooski River in Winooski Falls, Vermont. Its fifty year history is filled with innovation, success, expansion, fire, and eventual decline. The machine shop was just one of many companies to establish a factory along the East Canal Street, but its longevity is testament to its owner's persistence and resilience in the face of economic uncertainty.

In 1840, Avery Edwards and business partner Oscar White purchased a machine shop on East Canal Street formerly owned by the Burlington Woolen Company. This first incarnation of the business operated under the name Edwards and White. The new company ran at that location until a fire completely destroyed the shop in 1857. Shortly after the fire, Oscar White died. Edwards started a new business partnership with Alonzo Stevens, who had worked for Edwards and White in the machine shop as a millwright. Edwards and Stevens purchased the land where the former shop stood, and constructed a temporary wood building, while a new fire proof brick building was constructed. The new facility was a spacious 120 feet long and 40 feet wide with wings at right angles to the banks of the river. The company also secured 1/5 of the water power rights from the Winooski falls at the time of the land purchase. Fifteen men were fully employed at the shop in 1859, and in 1860, the company expanded operations to include a door, sash and blind department.1

In the mid-19th century, Avery B. Edwards established a machine shop along the Winooski River in Winooski Falls, Vermont. Its fifty year history is filled with innovation, success, expansion, fire, and eventual decline. The machine shop was just one of many companies to establish a factory along the East Canal Street, but its longevity is testament to its owner's persistence and resilience in the face of economic uncertainty.

In 1840, Avery Edwards and business partner Oscar White purchased a machine shop on East Canal Street formerly owned by the Burlington Woolen Company. This first incarnation of the business operated under the name Edwards and White. The new company ran at that location until a fire completely destroyed the shop in 1857. Shortly after the fire, Oscar White died. Edwards started a new business partnership with Alonzo Stevens, who had worked for Edwards and White in the machine shop as a millwright. Edwards and Stevens purchased the land where the former shop stood, and constructed a temporary wood building, while a new fire proof brick building was constructed. The new facility was a spacious 120 feet long and 40 feet wide with wings at right angles to the banks of the river. The company also secured 1/5 of the water power rights from the Winooski falls at the time of the land purchase. Fifteen men were fully employed at the shop in 1859, and in 1860, the company expanded operations to include a door, sash and blind department.1

Edwards and Stevens Machine Shop was an important part in Vermont's industrial revolution. They manufactured machinery, mill gears, lathes, planes, circular saws, and other machine tools that streamlined the manufacturing process. Machinery was regularly updated to state of the art equipment, and often included inventions by local Vermonters. Most notable was an automatic lathe, patented in 1887 by Frederick Baldwin of Brattleboro, Vermont. The machine's revolving blades was capable of producing a wide variety of turned woodwork. The new lathe worked rapidly and only needed two operators—one to feed timber into the devise, and another to remove the finished piece. Nearby mills and manufacturing factories were some of the company's biggest buyers of machined wares. In 1886, Edwards and Stevens supplied four mill turbines for the Chittenden Mill in Jericho, as well as about twenty tons of worth of shafts, gears, and pulleys. The machine shop also supplied the machinery for Catlin's mills in Winooski, and built the water wheel for Champlain Mill.2

Business came from all parts of Vermont, New York, and Canada. The company soon found they needed to expand their shop in order to keep up with machinery orders. They embarked on a massive expansion operation in 1866 that tripled the size of the factory. Two new structures were erected, a 124 ft. by 60 ft. brick building facing Canal Street, with a 155 ft. by 66 ft. wooden structure behind it. A central crane with a radius of about sixty feet and an internal rail system were added to streamline the manufacturing process. Two years later, Edwards and Stevens welcomed Frank Jubell into the partnership and reincorporated into Edwards, Stevens, and Company. A final addition to the complex was added in 1875. The building was 192 ft. by 62 ft. and extended from East Canal Street to the river front. It was considered the single largest room in Vermont next to the St. Albans railway shop. The new building contained two shafting lines, fourteen lathes, planers, drills, grinders, and other machinery tools. The basement was used as a wood shop, filled with several wood-working devises that were designed by the owners. The south end of the building housed the two water wheels the powered the facility, one powered the wood shop in the basement, the other powered the machine room. The total complex owned and operated by Edwards. Stevens, and Company included four storehouses, a lumber shed, a brick office, iron foundry, black smith shop, and a fire proof boiler house. The Burlington Weekly Free Press marveled that Edwards, Stevens, and Co. owned a "Small village of their own." 3 The small machine shop had grown into a complex industry.4

Despite a thriving and enterprising business, the last two years of the nineteenth century proved disastrous for the machine company. In 1898, a fire swept through the machine shop. The blaze started in a building rented to Mason & Co, just east of Edwards and Steven's Machine Shop. The flames spread rapidly, fully engulfing the two-acre factory complex, several tenements, and the lumber yard. The machine shop was "A total wreck" according to a newspaper report the following week. The destruction led to the unemployment of 150 workers.5

The next spring, perhaps sensing the company would not financially recover from the fire, Jubell sold his interest in the company. Edwards and Stevens worked to restore their company on a much smaller production scale, however, Edwards' health was failing and he died of a heart attack on July 14, 1899.6

Alonzo J. Stevens, now the sole owner, rebuilt the factory on a much smaller scale and reopened on April 1, 1900 with just eight employees. Stevens struggled to recover from the financial drain of the past two years, and was ultimately unable to generate enough profit to maintain the company. In 1901 it was put up for auction and sold to his son, Charles H. Stevens. Stevens, who had worked at the shop most of his life, reorganized the defunct company under the name Stevens Machine Company. The business operated for eleven years until Charles Steven's sudden death in 1911. The administrators of his estate sold the factory to the American Woolen Company in 1917 who used the shop to fabricate necessary components for its woolen mills.7

Notes (Edwards and Stevens)

2. "The Jericho Flouring Mill, The Roller Process Introduced to Vermont," Burlington Weekly free Press (Burlington, VT), Aug. 22, 1886; "Vermont Water Power," Burlington Free Press and Times (Burlington, VT), Dec. 22, 1910; "Baldwin's automatic lathe," Burlington Weekly Free Press (Burlington, VT), Aug. 9, 1867.

3. "The New Machine Shop of Edwards and Stevens," Burlington Weekly Free Press (Burlington, VT), Feb. 26, 1875.

4. "Death of A. B. Edwards", "Machine Shops," Burlington Weekly Free Press (Burlington, VT), Nov.16, 1866.

5. "A Fire Loss of Over $100, 000," Vermont Phoenix (Brattleboro, VT), Jan. 7, 1898.

6. Look Around Winooski, 9; "Chittenden County, Winooski," Burlington Free Press (Burlington, VT), Jul. 20, 1899.

7. Burlington weekly Free Press (Burlington, VT), Jul. 12, 1917; Burlington Weekly Free Press (Burlington, VT), March 26, 1916; Look Around Winooski, 11.