|

|

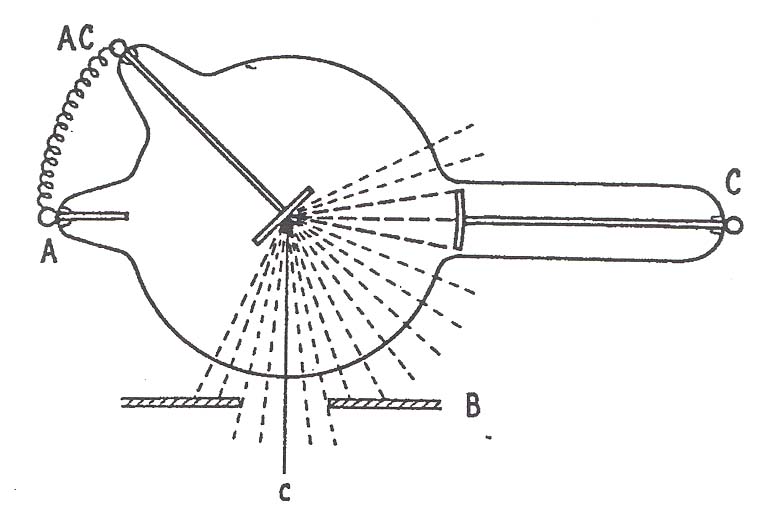

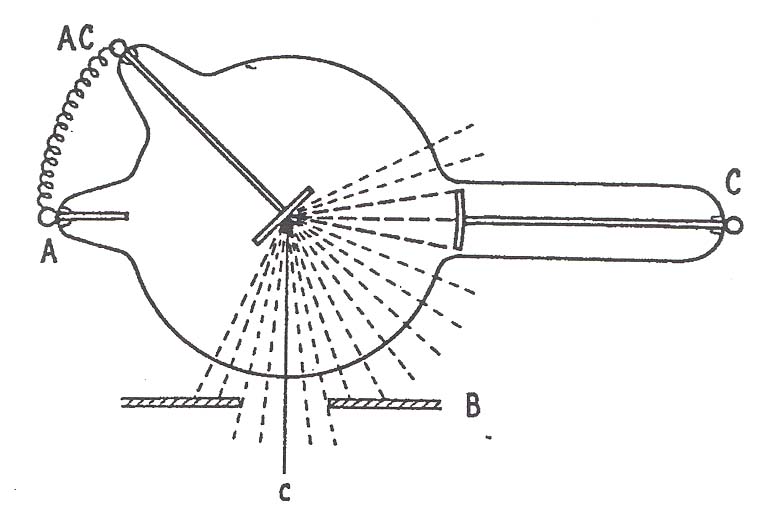

The figure above shows how three

electrodes can be placed in an X-ray tube. In this case the anode

(A) and cathode (C) are placed on the longitudinal axis of the tube.

The anode can be an aluminum stick or an aluminum stick with an end plate

perpendicular to the rod. The cathode has a concave spherical shape and

is placed to be nearly concentric with the glass sphere. The aluminum rod

of the anticathode (AC) supports a circular platinum plate (Platinum was

chosen for its high melting point and the fact that the radiation intensity

is proportional to the atomic number Z.) that is at a 45 degree angle with

the tube axis, and whose center corresponds to that of the cathode mirror.

The focused electrons from the cathode will hit the anticathode and X-rays

will be emitted in all directions (dotted lines). The useful beam is selected

by the diaphram (B).

As can be seen in the

figure, the tube is operated with the anticathode connected to the

anode and then both are connected to a positive voltage source.

The question that arises is wether or not two electrodes are sufficient,

a concave aluminum cathode and an anticathode with a platinum

mirror so that it functioned as an anode. British authors Pusey and Caldwell

(1904) wrote that "Many of the tubes of German manufacture have,

in addition to the two electrodes ... , a third which gives some advantage

in regulation of the resistance." As late as the 1920's, most German

X-ray tubes had the third electrode, but experts could not agree as to

whether it was important in the making or operation of the tube, or both.

No tube manufacturer has ever stated the advantage of having the third

electrode, in fact the shape of the electrodes was changed from one year

to the next. This confusion led Rontgen to state in a letter: "I do not

want to get involved in anything that has to do with the properties of

tubes, for these things are even more capricious and unpredictable than

women".

Albert Linberg (1956)

postulated that during the evacuation a strong alternating current is applied

in order to heat the glass and electrodes to facilitate degassing. During

this process the cathode and anode are connected together. If the cathode

and anticathode had been connected during this process, the platinum plate

would have been exposed to strong cathodic atomization during the half-cycles

of negative voltage. Only when the evacuation is complete are the

anode and anticathode connected together and from that time on the tube

should not be connected to a voltage of the wrong sign, since the atomization

from the anticathode would trap so much of the residual gas that the tube

would not function (the tube would become "hard").

Hans Vatter (1957),

however, thought that when the degassing takes place with an alternating

voltage of a few kV, the atomization of the anticathode would be negligable,

and the anode (A) should be of no consequence in the manufacturing process.

He demonstrated that anode is of great importance during the operation

of the tube in that it prolongs the life of the tube. He gave the

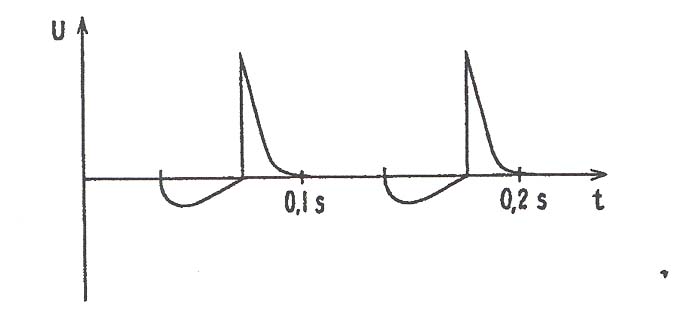

following explanation: the source of high voltage at the time was a Ruhmkorff

coil which supplies an alternating voltage of mostly

|

positive pulses, as shown in the figure. The tube is connected to the coil at the anticathode/anode junction. During the positive portion of the cycle the atomization is negligable. In the negative portion of the cycle the discharge prefers the longer way to the cathode from the anode rather than the path from the anticathode and atomization of the platinum is avoided. By inserting glow lamps into the leads to the anode and anticathode, Vatter could demonstrate that the current in each half cycle took different paths.